Project Grants 2011

Isotopic control for ultimate material properties

Principal investigator:

Erik Janzén professor of semiconductor materials

Co-investigators:

Lars Hultman

Joseph Greene

Igor Abrikosov

Institution:

Linköping University

Grant in SEK:

36.1 million over five years

Thus far the production process has been too costly, but now researchers at Linköping University believe they are close to solving this problem.

“We work with silicon carbide in several projects, one of which involves isotope-pure silicon carbide. We want to produce artificial silicon carbide consisting of as few isotopes as possible in order to achieve a material that can conduct away the heat that is generated,” explains Erik Janzén, professor of semiconducting materials at Linköping University.

These Linköping scientists have been studying silicon carbide since the 1990s. Erik Janzén is convinced that isotope-pure silicon carbide could improve the performance and reliability of components for electrical power, optoelectronics, and high-frequency systems. The purified material would also be better from the perspective of energy conservation. Insulation of nuclear fuel and spintronics, the foundation for quantum computers, are other possible areas of application.

30-percent increase

Erik Janzén is primarily interested in increasing the material’s capacity to conduct way the heat that is generated in the processes the material is used in.

“I believe it can be increased by 30 percent,” he says.

But there are a few lingering problems to be addressed before the researchers reach their goal, and a few more before mass production can be considered. One problem involves getting hold of the right kind of source material. Since natural silicon consists of three stable isotopes and natural carbon of two, the source material needs to be isotope enriched.

In the late 1990s there were high hopes for isotope-pure silicon. At that time the US funded a project in which Russian scientists were charged with producing isotope-pure 28silicon tetrafluoride . This assignment was given to Russian researchers in order to prevent them from being recruited to countries wishing to produce nuclear weapons. These scientists produced several kilos of material that was shipped to the US. But since the observable thermal conducting capacity of enriched silicon only increased by 10 percent, the project was ultimately abandoned.

“We have contacts with the owners of that material in the US and are very hopeful we will have access to the amount required for our project,” says Erik Janzén.

100% pure

The goal is to produce a material consisting of a single silicon isotope, silicon 28, and a carbon material comprising 100 percent carbon 12.

“Silicon carbide is a chemical compound consisting of pure silicon and one carbon atom. The carbon consists of 99 percent carbon 12 and one percent carbon 13. If, instead, you have 100 percent carbon 12 and replace the 8 percent of the silicon that contains isotope 29 and 30 with silicon 28, the conductivity should increase by at least 30 percent. Now we just have to prove it.”

Erik Janzén also has contacts with a Norwegian company that he hopes will be able to design a functioning technique for creating isotope-pure source material.

But besides needing sufficient material, the researchers also still have to find a reliable method for measuring the enhanced thermal effect.

“We’re busy developing a methodology and theory for measuring and calculating conductivity,” says Erik Janzén.

Tracking neutrons and photons

A total of nearly 60 people are working with semiconductor materials and silicon carbide in Janzén’s research team, five of them with thermal conductivity.

“The aggregate expertise of the group is invaluable to the project, and there are even more people involved and contributing to the project. Producers of high-frequency and light-emitting diode components are attracted by the specific properties of silicon carbide. LG Innotek has already been in touch with the Linköping researchers because they are interested in using the material to produce more powerful light-emitting diodes and transistors for electric hybrid vehicles.”

“That actually comes under an entirely different project. The grant from the Knut and Alice Wallenberg Foundation is primarily about thermal performance. Another part of the project is targeting boron carbide, which in its isotope-pure form can be of great significance for the detection and tracking, of neutrons and photons. We are also looking at the fundamental properties of ceramics,” explains Erik Janzén.

About silicon carbide

Silicon carbide, with the chemical symbol SiC, is a compound of carbon and silicon and was first produced in 1824, by the great Swedish chemist, Jacob Berzelius.

Owing to its hardness, silicon carbide is used as an abrasive, and as a result of its properties at high temperatures, it is suitable as a material in crucibles and ovens. Doped silicon carbide is also used as a semiconductor in electronics for applications with high voltage, high amperage, high frequencies, and high temperatures, as it does not exhibit such large energy losses as silicon-based electronics.

The hardness and heat resistance of silicon carbide also render it suitable for use in certain brake linings and in jets for rocket engines and space vehicles.

The material is also used in high-voltage facilities and mobile operators’ base stations and in the production of transistors. Silicon carbide is also the starting material for producing graphene. A new application is as a substrate for energy-efficient light-emitting diodes.

Text Carina Dahlberg/KAW

Translation Donald S. MacQueen

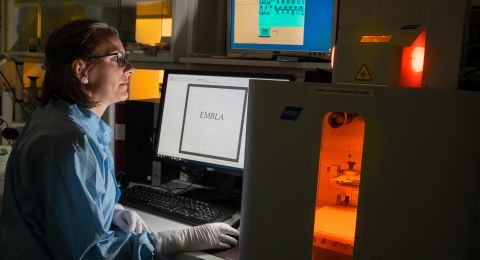

Photo Magnus Bergström