Project Grant 2015

Single Particle Catalysis in Nanoreactors

Principal investigator:

Christoph Langhammer, Associate Professor of Chemical Physics

Co-investigators:

Paul Erhart

Anders Hellman

Hanna Härelind

Kasper Moth-Poulsen

Henrik Sundén

Fredrik Westerlund

Institution:

Chalmers University of Technology

Grant in SEK:

SEK 35.9 million over five years

Nanoparticles are just a few nanometers across, i.e. billionths of a meter. They can be produced from many elements and substances. One example is palladium, which, when synthesized in a certain way, can form nanoparticles in the form of small cubes. Or rather: they are assumed to look like small cubes. In practice their appearance can vary significantly. Christoph Langhammer at the Department of Chemical Physics, Chalmers University of Technology displays a highly magnified electron microscope image of around two hundred particles.

“You see? Quite a number of them are cubes, but look here; these are more like sticks, and here they are spheres… Our project is about building tools to see the contexts in which differences between the particles impact catalysis. We think it is necessary to study one particle at a time to get to the bottom of this,” says Langhammer, who is leading the project.

Studying both the catalyst and the product

The researchers will use the nanoreactor to study what happens to the nanoparticle during catalysis, and how it is affected by factors such as changes in pressure, reactant composition and temperature. It might change shape, be oxidized – emit or absorb electrons. This may affect how effective it is, or what reactions it drives.

The reactor will also enable the team to study the substances undergoing catalysis. If different forms of the nanoparticle result in different final products, this may help other researchers to design nanoparticles enabling more efficient catalysis with fewer hazardous or unwanted by-products.

The nanoreactor also offers new potential for quantum physicists. At the nanoscale, quantum physics is often needed to explain how particles and catalytic processes behave.

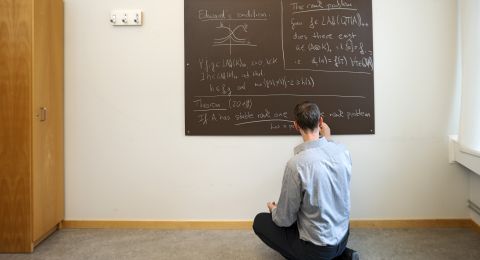

“Quantum physicists cannot perform computations on actual systems containing millions of particles differing from each other. They make theoretical computations based on one particle at a time. So our experiments will be almost directly comparable with their computations. We hope to prove the validity of those computations, and they may be able to present concrete suggestions based on them, which we can test in our experiments,” Langhammer adds.

New ideas for making the reactor

There are a number of potential methods of making the tiny reactor. Nanolithography involves “writing” an electron beam on a substrate where the reactor and the nanoparticle are ultimately formed after a number of “etching” and material deposition steps. It consists of a narrow channel in which a nanoparticle is grown so as to remain in place. A lid is then placed over it; liquid or gas is pumped into the channel, and the result of the reaction between the fluid and the catalyst nanoparticle in the reactor comes out on the other side, where it is analyzed.

An alternative approach to using nanolithography for making the nanoparticle in the reactor is to use colloidal synthesis and that everything to be examined is allowed to flow through the reactor dissolved in a fluid. This has not been tried before, but the researchers at Chalmers are confident that it will work.

Instruments can’t cope with the pressure

“We would really prefer to carry out our experiments under conditions resembling catalysis in reality. This means high temperatures and at least atmospheric pressure. But this is a challenge. Scientific instruments that are sensitive enough to probe such small particles one at a time usually work only under very low pressure,” Langhammer explains.

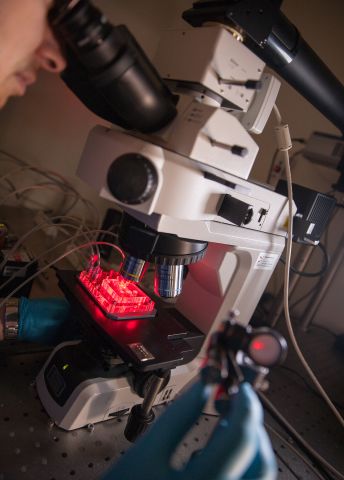

So the researchers are looking for other detection methods. One approach they want to try is to use a phenomenon that occurs when metal nanoparticles are illuminated with visible light. This causes the color of the particle to vary, depending, for example, on its size, its shape or whether it has been oxidized. The color change is visible in a conventional microscope, and its detection is not affected by either pressure or temperature.

Helping other researchers

In all, there are seven research leaders that together run the project. They include theoreticians, an organic chemist, an expert on catalysis, an expert in nanofluidics, and a specialist in the synthesis of nanoparticles. Langhammer himself is a materials scientist and expert in nanooptics and nanofabrication. All this expertise is needed.

“Our aim is to develop this experimental platform and show that it is in fact possible to study individual nanoparticles under conditions relevant for catalysis by fairly simple means. I don’t want to spotlight any particular reaction where I think we can solve a specific problem – that’s not the main aim of the project. But we are convinced that the reactor and the entire concept will help future catalysis researchers in their efforts to develop the best catalysts for practical applications,” Langhammer comments.

Text Lisa Kirsebom

Translation Maxwell Arding

Photo Magnus Bergström