Project Grants 2011

The Swedish graphene initiative

Principal investigator:

Mikael Fogelström, professor of theoretical physics

Co-investigators:

Chalmers

August Yurgens

Herbert Zirath

Linköping University

Rositza Yakimova

Uppsala University

Ulf Jansson

Olle Eriksson

Institution:

Chalmers University of Technology

Grant in SEK:

40.8 million over five years

Funding from the Knut and Alice Wallenberg Foundation is making it possible to form a group comprising some 30 graphene researchers working in close collaboration. "The Swedish graphene initiative" is slated to be an elite effort that will make its mark in international competition.

“In this way we can bring together our different competencies among the foremost scientists in materials research and create cross-disciplinary collaborations. The funding will be used to develop methods for producing graphene, but also to develop various components, as well as to perform a good deal of important basic research,” explains Professor Mikael Fogelström, who is coordinating the project.

Graphene is without doubt the hottest material in the research world. It has been so for a few years, ever since Kostya Novoselov and André Geim managed to produce graphene in 2004. They won the Nobel Prize as early as 2010, unusually quickly, and research teams the world over are now competing to stake claims on new knowledge.

New production method from Sweden

A pressing question is how to improve the production process. Thus far it has been rather costly and difficult to produce high-quality graphene. Discoveries at Chalmers and Linköping University have therefore attracted worldwide attention.

The original production method involves removing layer after layer from graphite until there is only a single atomic layer remaining. The method is called exfoliation, and the tool is ordinary tape. Until now it has been the best way to make graphene of good quality, but the downside is that the method cannot be scaled up to manufacture large quantities.

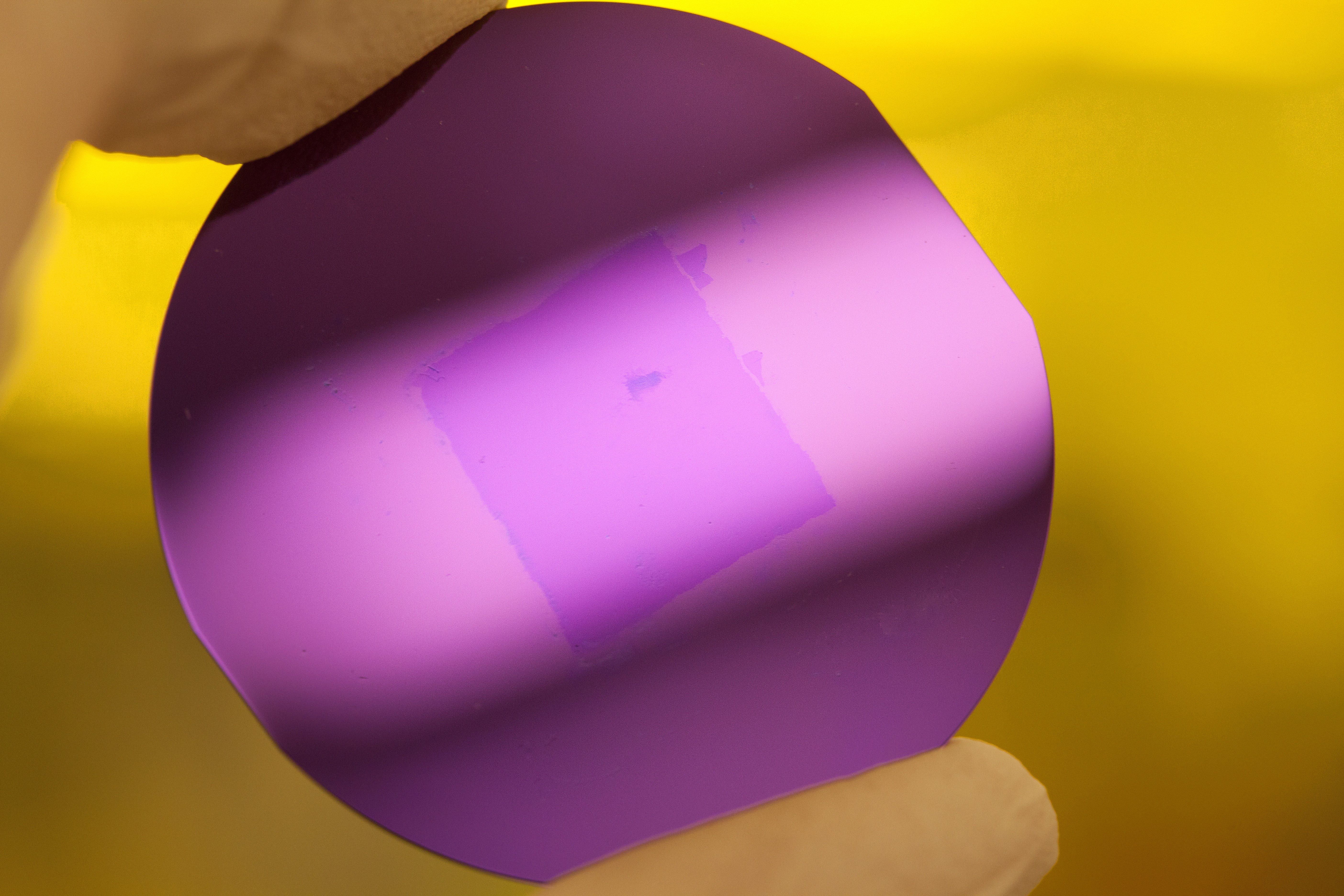

Instead, the Swedish researchers start with silicon carbide, a mixture of silicon and carbon, and heat it up. This vaporizes the silicon, leaving an atomic layer of carbon. The method is considerably easier to use in industrial production and is moreover beginning to attain levels of quality equal to exfoliated graphene.

“We actually have a shortage of graphene, since the supply is so limited. That’s why it’s important to be able to develop and improve synthetic methods in order to create large graphene surfaces,” says Mikael Fogelström.

This technique now serves as the basis for a spin-off developmental company in Linköping, Graphensic, which is one of the world’s few graphene manufacturers, with Professor Rositza Yakimova as its CEO. The first customers are primarily research groups in Sweden, Japan, France, and a few other countries.

Wide-ranging basic research

At the same time as these researchers are refining production methods step by step, other basic research remains to be tackled. This involves examining and treating graphene at the nano level to see what happens if the material is altered in various ways, whether it can be combined with other elements, or how holes in the structure affect the movement of electrons.

“Graphene is a huge molecule, and it would be interesting if we could functionalize it and get it to attach to other molecules with specific bindings. For instance, you might be able to get it to bind to various parts of DNA or exhaust fumes, so you could quickly and precisely measure the content.”

The material’s special properties, such as flexibility and transparency, also fuel interesting ideas about what future computers might look like.

Paves the way for harmless x-rays

Rapid electronics has long been a hallmark at Chalmers, and one vision is to use graphene also in terahertz radiation. The electromagnetic waves in the terahertz range make it possible to see into the body without using harmful x-rays. The radiation is moderated by water and therefore stops after about a centimeter. But it is precisely its sensitivity to fluids that makes it possible to create an image of various tissues in the body, or to see through clothing, for example.

Terahertz radiation requires materials whose electrons can move extremely rapidly, and there are great hopes for graphene. A team directed by Jan Stake has already constructed a graphene transistor that works at more than 10 gigahertz. This research is now proceeding into the terahertz range, that is, more than 100 gigahertz, which opens up entirely new possibilities.

“This could lead to soft x-rays for applications in biomedicine or security, at airport checks, for instance, where there has been a lack of suitable component materials to deal with sufficiently high frequencies,” says Mikael Fogelström.

Another future scenario is short-distance radar that can penetrate fog and rain up to a hundred meters, which might facilitate driving in bad weather.

“Graphene has a tremendous number of possible applications, and we are just getting started in our work to develop it. But thanks to the collaboration we’re setting up with various research teams, we have a good chance of developing new applications together and helping Sweden hold its own in an international perspective,” claims Mikael Fogelström.

Text Nils Johan Tjärnlund

Translation Donald S. MacQueen

Photo Magnus Bergström