Project Grant 2011

Aerotaxy to grow nanowire

Principal investigator:

Lars Samuelson

Institution:

Lund University

Grant in SEK:

SEK 18.9 million

In the past 20 years, nano technology has become one of research’s front lines. Now, it is not only possible to explore, but it is now also beginning to be possible to control material properties in this world invisible to the eye. It is laying the foundation for a new technical leap, which without exaggeration could revolutionize life on Earth.

Great hope is being tied, for example, to semiconductive nanowires. Among other things, they can be designed as sustainable LEDs and in the future could replace all of the world’s light bulbs. Nanowires can also become a key component in highly efficient solar cells with an operating efficiency of more than 50 percent.

Data can be stored for thousands of years

Other applications are the development of new computer memory, which in theory can store information for thousands of years, and within medicine, where nanowires can be used to control the growth of stem cells or to connect together nerve cells with mechanical prostheses.

But before all dreams become reality, an effective and inexpensive method is needed that enables mass production of nanowires with a perfect crystal structure, uniform size and material composition. Researchers at Lund University have now made considerable progress, which has incited interest the world over, explains Professor Lars Samuelson, Head of the Nanometer Structure Consortium at Lund University.

“We call the method aerotaxy and with it, we have succeeded in achieving perfect crystalline nanowires in an exceptionally fast growth, up to thousands of times faster than with earlier methods.”

Began in Japan

It all began in the 1990s, when Lars Samuelson was a visiting research fellow in Tokyo. A colleague at Hitachi had succeeded in producing super thin wires of the semiconductive material gallium arsenide using small points of gold as a starting point.

“The gold particle controls the growth of a semiconductor rod, a thin wire that we then called a quantum wire or nanowire. It is a crystal structure that is a monolithic growth from the gallium arsenide. The funny thing is that the discovery was actually made by mistake.”

Already then, Lars Samuelson realized that it would be possible to let the wires grow under controlled conditions and on the long term use them as electronic components.

The research gained speed and in 2002, three scientific articles from Lund University, Berkeley and Harvard were published almost simultaneously that showed that it was possible to change the atomic composition and combine different substances in a nanowire.

The results gave a taste for more and the research has since very much been a matter of how to make production more efficient.

Grows in an oven

The original method through epitaxy is slow and expensive. There, a semiconducting material like gallium arsenide is used as a substrate and gold particles are placed on the crystalline substrate.

“But we began to wonder whether the substrate is really necessary,” says Lars Samuelson.

The idea was born to instead let the gold particles and semiconducting substances float freely around in an aerosol phase with hydrogen gas as the carrier gas. All ingredients were stuffed into an oven with a temperature of around 400 degrees Celsius. And the results exceeded the expectations.

“At the end of the oven, we obtained perfect crystalline nanowires that grew in the right direction and at a new dynamic speed. Of course, it means a great deal that we can now produce a material with a thousand times higher growth rate, and it could be a base for a new Swedish materials industry,” says Lars Samuelson.

Support for in-depth research

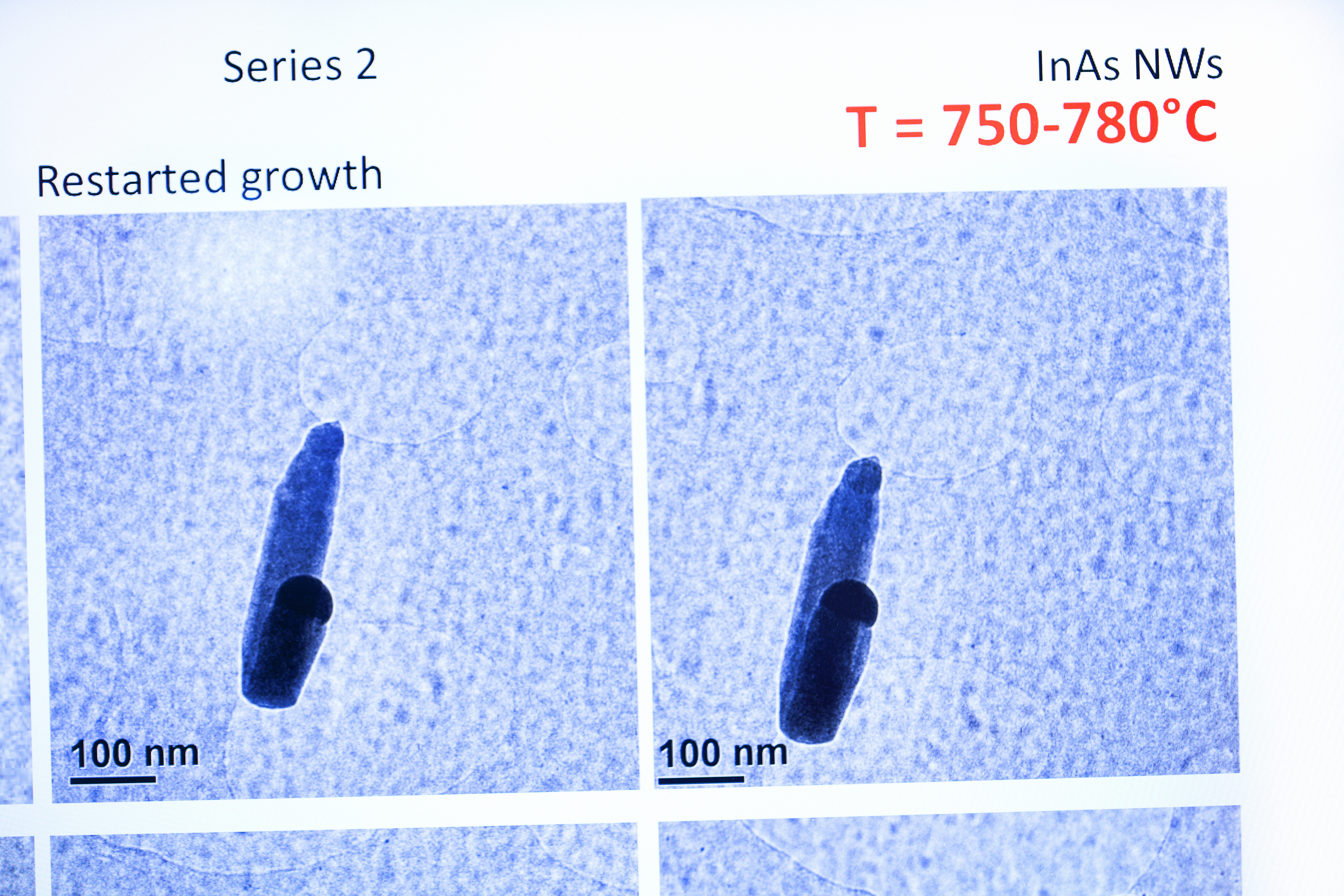

Through a grant from the Knut and Alice Wallenberg Foundation, the researchers now have the opportunity to explore the method further. A challenge is to understand on an atomic scale how the nanowire is built up and grows in the aerosol phase. Another challenge is a matter of optimizing the conditions in production. They are also developing unique pictures by using transmission electron microscopy and x-ray diffraction, to follow the growth in real time. The first report from this entirely new research has just been accepted for publication in the journal Nature.

Time is also devoted to conceivable applications. The research in Lund has already resulted in companies: Sol Voltaics, which develops solar cells, and Glo, which develops LEDs. Lars Samuelson has a vision that nanowires can contribute to solving the world’s energy problems, in part by saving energy.

“One of the ways of saving energy with the best ROI is based on replacing light bulbs with super-efficient LEDs. More than 20 percent of the energy consumption goes to lighting and if it is possible to make this more efficient by a power of ten, a number of nuclear power plants can be closed,” says Lars Samuelson.

On one side of the scales is energy-saving technology, and on the other, ultra-efficient and inexpensive solar cells can be discerned, based on nanowires with more than 50 percent efficiency.

“I personally see this vision as something very attractive, but these two overall objectives presuppose very challenging material physics, component physics and exciting new system solutions, also in close cooperation with companies,” says Lars Samuelson.

Text Nils Johan Tjärnlund

Translation Semantix

Photo Magnus Bergström

Summary:

Researching a new method, aerotaxy, for the production of nanowire, with great potential in LED lighting and high-performance electronics, among other areas.

Detailed studies of fundamental questions concerning the new growth mechanism and development of the aerotaxy method.