Project Grant 2019

Towards CO2-neutral energy conversion using advanced laser diagnostics and modeling – COCALD

Principal investigator:

Professor Marcus Aldén

Co-investigators:

Lund University

Xue-Song Bai

Alexander Konnov

Elias Kristensson

Zhongshan Li

Institution:

Lund University

Grant in SEK:

SEK 34 million over five years

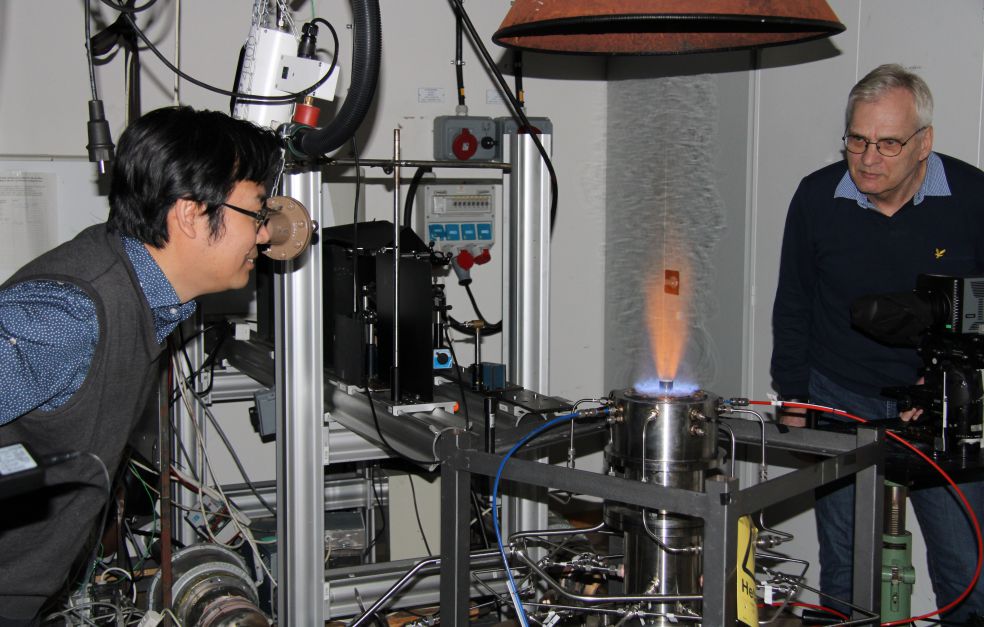

Although there has been an accelerating expansion of solar and wind power over the past few years, more options are needed to replace energy from the burning of fossil fuels. Since the 1980s Marcus Aldén and his colleagues at Lund University have developed a number of laser diagnostic techniques capable of analyzing various combustion processes at atomic level. They are now conducting a new project focusing on combustion of metal in powder form.

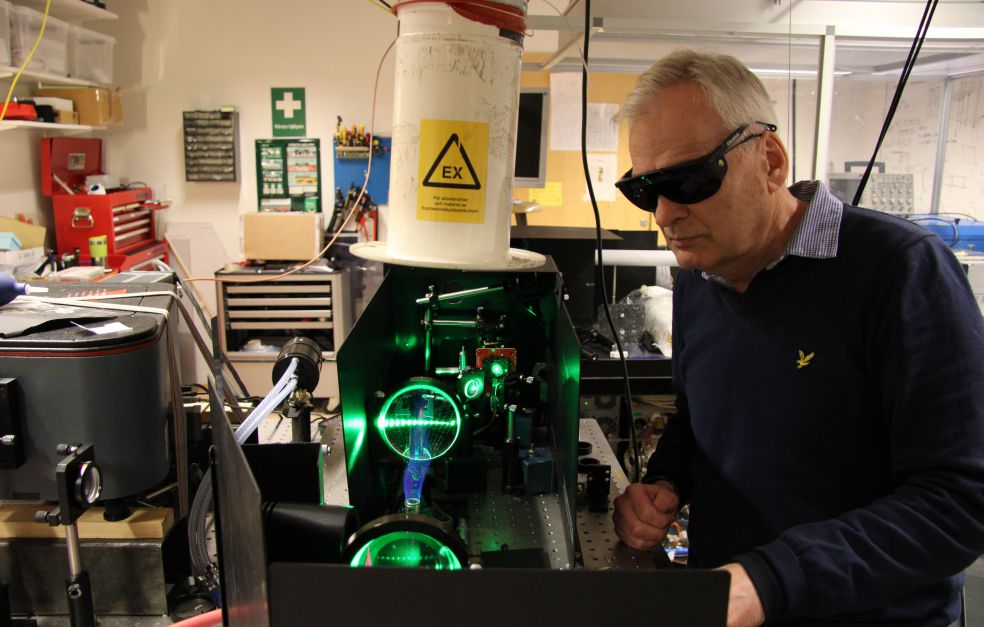

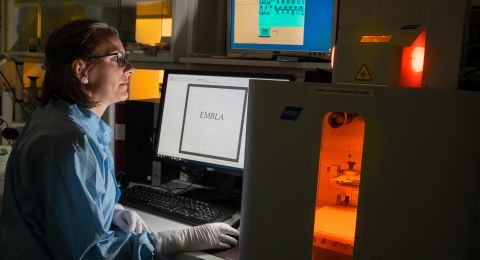

“We have world-leading equipment using advanced laser technology and detection devices for non-intrusive measurements at high spatial and temporal resolution. It gives us unique opportunities to validate new combustion models,” Aldén explains.

Undeserved bad reputation

Aldén considers there are several advantages to be gained by replacing fossil fuels with metals like iron, aluminum and silicon. These elements are common in the Earth’s crust, and also have high energy content. But best of all – no carbon dioxide is produced when they are burnt.

“Combustion has acquired an undeserved bad reputation due to the problematic fuels we have used. There is nothing intrinsically wrong with combustion, which is a reaction at high temperature. Combustion is an ideal way to extract energy,” Aldén says.

A further aim is to create a cycle in which the residual products of combustion are converted back into metals using “green electrolysis”, i.e. electrolysis using only electricity from renewable energy sources.

But the challenges are many, and several of them are as yet unknown. Aldén elaborates:

“We don’t yet know anything about how pressure-dependent the process may be, how turbulence affects combustion, or whether nitrogen oxides will be formed and require treatment. That’s why the project is based on close interdisciplinary collaboration.”

International collaboration

Researchers will contribute their expertise in fields such as fluid dynamics, chemical kinetics and thermodynamics. Additionally, the team is collaborating with Eindhoven University of Technology and McGill University in Montreal, Canada, which are among the few places where studies have been made of metal combustion.

“To be honest, I’m no expert on combustion, but I have long experience of development and application of laser-optical measurement technologies. That’s why it’s so important that we establish collaboration with colleagues whose expertise complements our own, and who can interpret and analyze our findings,” he says.

Pulsed lasers are used in laser diagnostics to take measurements for extremely short periods during which the laser beam can be focused on a very small area. The technology makes it possible to measure at several points simultaneously, and also in multiple planes or volumes.

Simply put, measurements are taken when a laser beam strikes molecules and atoms, which in turn “reflect” the light. The identity of the molecule struck is revealed, among other things, by the color of the light emitted. Laser diagnostics can be used to determine concentrations of substances, temperatures, velocities and particle sizes. The main advantage of the technique is that it is non-intrusive, which prevents the measurements from interfering with the process.

“The practical experiments play a key role, since we can modify the conditions as we proceed to see whether and how combustion is thereby improved. We can also use modeling to take steps towards a better understanding.”

One way of improving the process is to use plasma, in the form of electrical energy, to help stabilize it.

“It’s a long shot, but we have to try it out, in the hope that it might actually work.”

The researchers’ work is based on findings from an earlier project, also funded by Knut and Alice Wallenberg Foundation, in which laser diagnostic methods were used to study gasification, catalysis and nanotechnology.

Burning ammonia

The project also includes new ways of burning ammonia, another substance whose combustion does not form CO2. There is great interest in burning ammonia among industrial operators looking for fossil-free options. Aldén elaborates:

“Unfortunately it burns poorly and generates nitrogen oxides. We need to understand what happens, and how we can prevent it. One potential way of improving efficiency is to burn ammonia in combination with hydrogen gas.”

Hydrogen is widely expected to play a key role as a future energy carrier, and combustion of metals can also result in its formation. Aldén envisions two kinds of combustion methods: one to make use of the heat generated, the other where metal particles – aluminum in particular – are induced to react with steam, producing hydrogen gas.

Aldén stresses that many unresolved questions remain. Moreover, a system analysis is needed to determine how this field can serve as a complement to other renewable energy sources.

“It’s far too early to say that we will be installing metal burners in our homes. But there are so many advantages – an ample supply of fuel, high energy content, and we avoid carbon dioxide. There is every reason to pursue this avenue.”

Text Magnus Trogen Pahlén

Translation Maxwell Arding

Photo S. Li, J. Huang, C. Brackmann