As a battery researcher, Kristina Edström has seen her subject shed its dull reputation. Batteries are now a hot topic – a field in which new discoveries have the potential to change the entire course of societal development. One aim is to create “self-healing” batteries, inspired by processes in nature.

Kristina Edström

Professor of Chemistry

Wallenberg Scholar

Institution:

Uppsala University

Research:

Lithium ion batteries from a materials chemistry perspective, particularly anode materials. Development of new battery chemistries such as lithium–air, lithium–sulfur and sodium ion batteries.

Nowadays batteries represent a key technology in many fields. In a world of interconnectivity, there is a growing demand for strong, long-lasting batteries. And as countries around the world strive to achieve their climate targets, more powerful batteries are essential for the transition to electric automobiles and other battery-driven vehicles.

So Edström does not think it is any way remarkable that battery research is attracting such huge interest. She is a professor of chemistry at Uppsala University, and Director of the Ångström Advanced Battery Centre. But things were different when she was working on her doctoral thesis in the late 1980s.

“At that time batteries were dismissed as nothing more than deathly boring boxes. Many scientists considered battery research to be soulless.”

Pure science fiction

Edström has always had a passion for chemistry, and is driven by a desire to understand its fundamental mechanisms. She has also learnt to appreciate applied research, as batteries have come to play an ever greater part in our daily lives. She recalls a meeting with Ericsson, the telecoms company, in the mid-1990s, and the visions that were laid out at the meeting.

“They talked about making telephones much smaller – that they would be able to play music and send electronic messages. We were astounded – we thought it sounded like pure science fiction.”

The technology that sounded like a pipe dream back then is now a part of everyday life, thanks to the breakneck speed of developments.

“Batteries got better, giving birth to completely new applications. But not only that – our behavior has also changed far more than we could have envisioned.”

Edström believes the time is ripe for battery development to move on to the next step. She anticipates improving numerous properties of batteries.

“We want more energy – more output, longer life and no loss of performance over time. We also want to make safer batteries that are extremely cheap and do not require critical raw materials.”

Self-healing batteries

The wish list is long, and Edström has chosen to focus on a few things at a time. In one ongoing project, she has been inspired by processes in nature to create durable batteries that are to some extent self-healing.

A battery cell consists of three main components: two electrodes and an electrolyte. Inside the cell the electrodes are in contact with each other via the electrolyte – a material capable of conducting ions but not electrons.

Rechargeable batteries suffer constant wear due to various side reactions taking place in the cell. The ions, e.g. sodium or lithium ions, travel back and forth constantly as the battery is charged and discharged. The chemical process continues until the electrodes wear out. At that point the cell has lost all its energy.

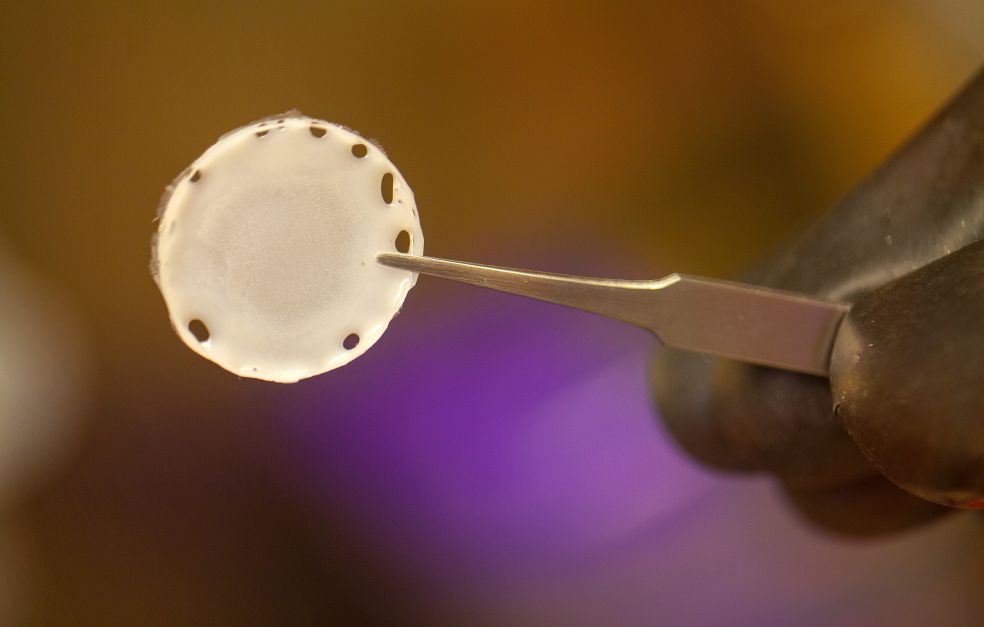

“Over time the surface of the electrodes becomes pitted, and the battery gradually loses its capacity. We’re now trying to manufacture what we call ‘self-healing polymers’ that can be used as a protective coating on electrodes so their surface lasts longer.”

The goal is to identify different types of polymer – molecules made up of multiple repeating units – that can easily be linked together to form the protective coatings. The different types of polymer will then be synthesized and analyzed electrochemically using spectroscopy. The next stage is to model the interfaces between electrodes and electrolyte to ascertain how the polymers bond to the electrode surfaces.

“We also want to find out whether it’s best to allow the polymers to act from the outset, or whether there should be a stimulus in a given situation, triggering them into action.”

A similar concept exists in pharmaceutical manufacture, where a drug can be encapsulated in particles, to be released later on in the body by means of a stimulus or after a predetermined time.

Completely new batteries

The research may ultimately result in batteries that can be used at much higher or lower temperatures than current models, and safety can be improved by avoiding overheating. More robust batteries can provide the impetus for sweeping societal changes. Edström elaborates:

“There is much talk of electric cars and the automotive industry, but there will also be exciting new developments in the medical field. Batteries can be miniaturized for use in diagnostics, artificial muscles, and major initiatives in robotics within the health and medical care sector.”

Another goal is to produce more eco-friendly batteries. Minerals are needed to achieve a high energy density, but the researchers are increasingly turning their attention to cellulose-based materials.

“We are collaborating with Stora Enso on a project involving residues from pulp and paper manufacture. The idea is to carbonize them, i.e. boil them down into carbon particles, which can then be used to make electrodes.”

“When I was a young researcher, grants of this kind were not available – I had to make my own way the best I could. So it’s a wonderful feeling for someone of my age to receive this acknowledgement by being chosen as a Wallenberg Scholar. I hope my research manages to live up to expectations.”

As a Wallenberg Scholar, Edström hopes first and foremost to arrive at a description explaining how the processes in self-healing molecules work in the context of batteries. But she is also keen to see the results put to use in an actual battery.

“It would be an added bonus if we could develop batteries that can be used in real life.”

Text Nils Johan Tjärnlund

Translation Maxwell Arding

Photo Magnus Bergström