Project Grant 2019

Photofunctional Iron Complexes

Principal investigator:

Professor Kenneth Wärnmark

Co-investigators:

Uppsala University

Reiner Lomoth

Lund University

Petter Persson

Reine Wallenberg

Arkady Yartsev

Institution:

Lund University

Grant in SEK:

SEK 35 million over five years

Professor Kenneth Wärnmark usually jokingly calls what he does “modern alchemy”. In the olden days alchemists attempted to turn base metals into gold. Wärnmark is leading a project funded by Knut and Alice Wallenberg Foundation to create something less lustrous – but nonetheless valuable: iron capable of providing less expensive and more eco-friendly energy.

The unsustainable forms of energy that currently predominate must be quickly replaced with alternatives such as solar energy, which is available to us in unlimited quantities. That energy can be converted into electricity using solar cells, producing easily enough to meet global needs. But the materials used in solar cells impose limits. Silicon-based solar cells are the current market leaders, with dye-sensitized solar cells a rapidly growing challenger. Both kinds present their own challenges. Silicon requires expensive and energy-intensive purification. The dyes used in the new cells are generally rare elements, such as ruthenium. Wärnmark and his colleagues in Lund and Uppsala are now modifying iron molecules so they can replace ruthenium in solar cells.

“Ruthenium is an uncommon and costly metal, whereas iron is the second most common heavy element in the Earth’s crust. They belong to the same group in the periodic table, and share certain properties. But iron in its natural state cannot be used in a solar cell. We’ve found a solution to that,” Wärnmark says.

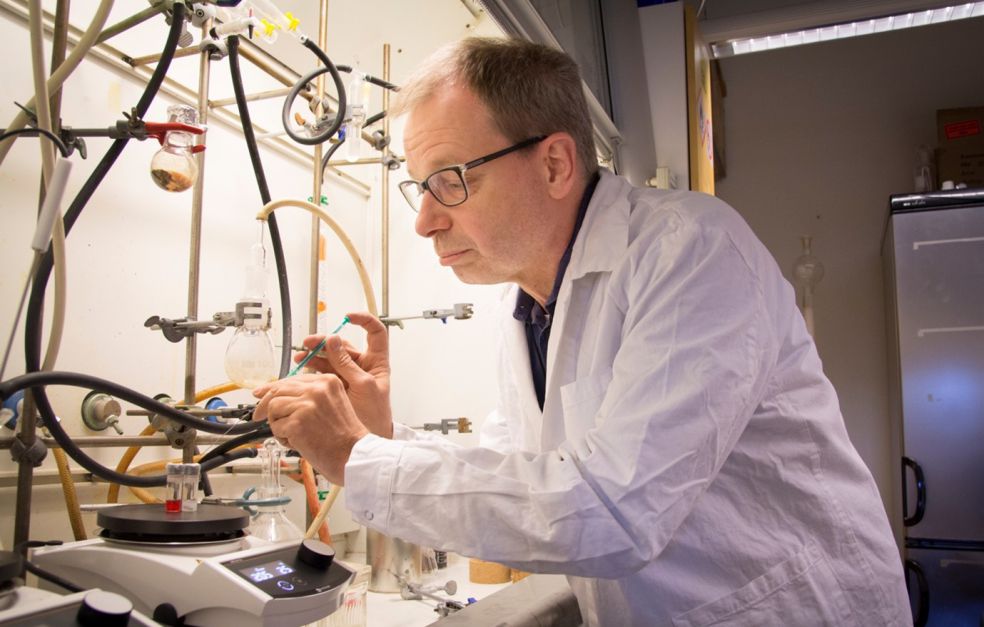

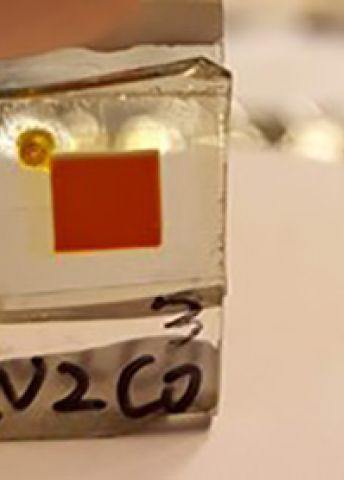

The solution is to induce the iron to bind to other substances, known as “electron-donating ligands”. The resulting complex can induce electrons to behave in exactly the right way for use in a solar cell. It must be possible for sunlight to “excite” them so they acquire higher energy, and retain that energy long enough for the complex to release an electron to a semiconductor in the solar cell, thereby creating an electric current.

Indoor solar cells the first step

Dye-sensitized solar cells are less efficient than their silicon-based counterparts. Using iron instead of ruthenium further reduces their efficiency, but the researchers recently managed to achieve one-percent efficiency, and they expect to achieve five percent within a few years. That would be enough to render the iron complex commercially viable. The first step is to produce small solar cells for indoor use.

“When we started out, I had big ideas, like going to LKAB (a major iron and steel producer), and saying ‘you should stop making steel and start making solar cells’! Fortunately, however, we have a commercial and technical reference group who helped us to realize where we should start.”

The new technology is even better suited to indoor cells, which absorb stray light from windows and lighting. Cells of this kind could drive sensors and small electrical devices such as mobile phones, replacing batteries. Here too, material shortages are expected as ever-growing numbers of objects are electrified and connected up to the internet of things. Wärnmark describes it as a staging post before the research moves on to larger-scale solar panels for outdoor use.

Future need for eco-friendly hydrogen gas production

Another line of research is hydrogen gas production. Hydrogen is often described as the green energy source of the future, since the only by-product from burning it is water. LKAB is planning a major transition to the use of hydrogen for its blast furnaces, and the EU Commission has launched a hydrogen gas strategy involving investments of several hundred billion euros. All that is needed is climate-friendly manufacturing techniques. Current hydrogen gas production produces carbon dioxide emissions of one hundred million metric tons a year in the EU alone.

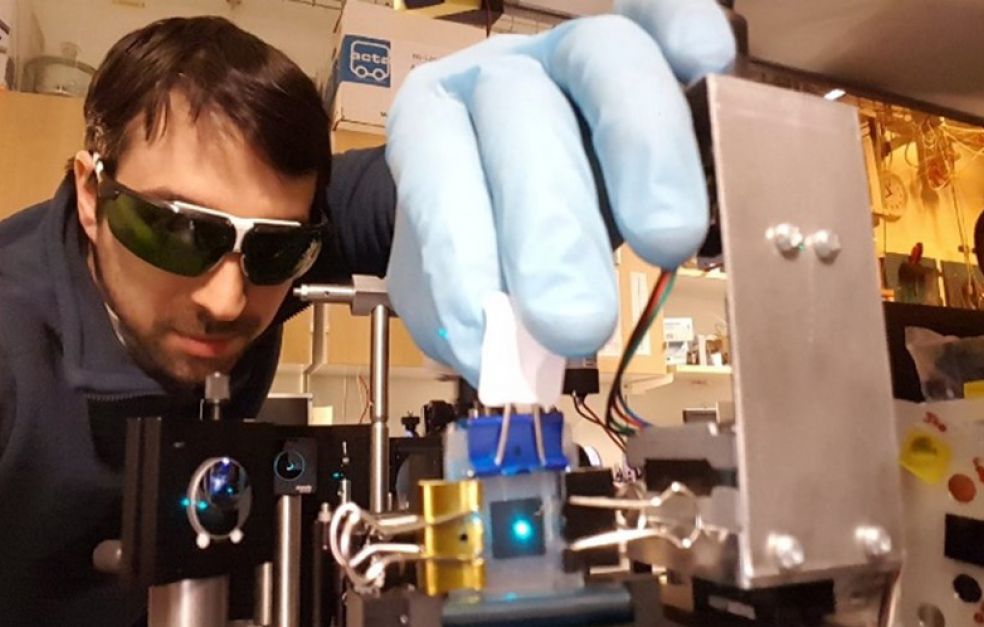

“Ninety-eight percent of all hydrogen gas is produced using fossil fuels. This is a problem we need to address. We’re working on new iron complexes that catalyze the reduction from water and sunlight to hydrogen gas. We’ve built a prototype hydrogen gas catalytic converter, and we’re just about to start using it.”

Iron complexes can also catalyze reactions involved in manufacturing fine chemicals such as drugs, and in some circumstances seem to be more efficient than the catalysts in use today. Wärnmark points out that the project has taken several directions that he had not originally foreseen.

“The large size of our research team increases the likelihood of unexpected discoveries. It’s really interesting.”

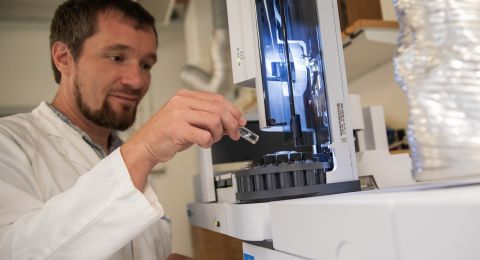

The project involves researchers with a variety of competencies, from the basic scientific design and synthesis of the new ligands, to expertise in photophysics, electrochemistry and solar cell technology. The current focus is very much on developing more ligands in order to create more dyes, and figure out which have the greatest potential.

“The chemistry is complicated. So far we’re only at lab scale, and we’re using every trick we know. But when we have found a real winner, I think that the process know-how available in Sweden will enable us to manufacture the complexes efficiently and at scale. Within five years I think this project will have developed a prototype hydrogen gas catalytic converter – and definitely an indoor solar cell prototype.”

Text Lisa Kirsebom

Translation Maxwell Arding

Photo Kennet Rouma, Linnea Lindh, Pavel Chábera, Nils W. Rosemann, Johan Joelsson