Hans Hertz

Professor of Biomedical Physics

Wallenberg Scholar

Institution:

KTH Royal Institute of Technology

Research field:

X-ray physics

Wallenberg Scholar

Institution:

KTH Royal Institute of Technology

Research field:

X-ray physics

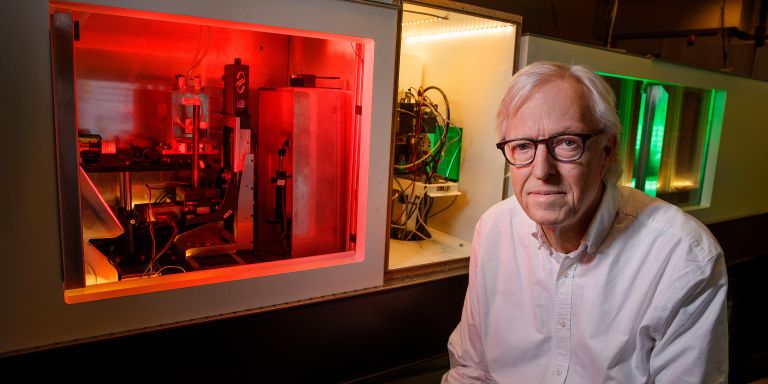

Hertz has achieved a true technological breakthrough in X-ray technology: a method that provides sharper images and better contrasts with shorter exposure times. The technique is based on a new X-ray source: liquid-metal-jet technology, which replaces the positive anode in an X-ray tube with a jet of liquid metal. This makes it possible to increase the power output from a small spot with no risk of overheating.

The increased power dramatically enhances image quality. Hertz has been developing this imaging technology since 2006, one goal being to improve medical diagnostics. Although the technology has not yet been clinically adopted, Hertz now sees a clear application.

When a tumor is surgically removed, the tumor tissue is sent for analysis to confirm that the operation was successful. The analysis determines whether all tumor cells were in fact removed during surgery, but this process often takes up to a week.

“Our goal is to enable assessments while the patient is still on the operating table. At that moment, the surgeon should know whether the entire tumor has been removed or if additional treatments are required. Achieving this requires a new type of X-ray technology with greater detail than is currently available,” says Hertz.

The healthy tissue that is removed is called the resection margin. If tumor cells are found there, the patient will need further treatment, such as additional surgery, chemotherapy or radiotherapy.

Removed tissue can be analyzed in several ways, often involving multiple manual steps. Typically, the tissue is embedded in paraffin, sliced into thin sections, stained and examined under a microscope by pathologists, who determine whether any tumor cells remain.

Using high-resolution X-ray technology for analysis opens up the possibility of instantly scanning the tissue sample for residual cancer cells.

“The clinical benefits will be enormous if we can replace current time-consuming manual methods. We are now making health economic calculations to demonstrate the potential of our method.”

But before the technology can be utilized, it must be adapted to fit into the healthcare workflow. This is being done in collaboration with Karolinska University Hospital, with tests conducted on some ten different cancer types.

The liquid-metal-jet technology was a classic breakthrough. Breakthroughs like this open up many new opportunities for research. You need their impetus to avoid playing the same tune throughout your career.

“The next step is to install our X-ray equipment at a clinic at Karolinska University Hospital in Huddinge, south of Stockholm, so that samples can be analyzed immediately during surgery,” says Hertz.

Hertz is also exploring broader clinical applications of the technology. There are detailed simulated models of the human body that can be used to conduct virtual clinical tests. These digital models will be used to evaluate the X-ray technology for use in diagnosing lung diseases.

Hertz is leading the development of new computational methods that could form the foundation for a future clinical system.

“We will not build an entire system but will work out which parameters are relevant for creating such a system, such as required exposure times and the type of detector needed.”

The team also needs to improve their understanding of what it means to visualize details in the body that were previously invisible, such as very small airways or the thickening associated with asthma.

Interdisciplinary collaboration is key to success, so Hertz’s research team includes physicists, biologists, clinicians and computation experts.

“Some people might consider the breath of competencies overkill, but if you want to create something genuinely useful, you need access to broad scientific knowledge.”

The development of liquid-metal-jet technology laid the foundation for Excillum – a spinoff company. This technology is used to manufacture systems that can analyze chemical substances, inspect batteries or detect defects in microelectronics. The idea came to him one evening while biking home after a discussion with a doctoral student.

At the time he was working closely with the student to find a simpler and cheaper way to use laser plasma as an X-ray source.

“While biking home, I came up with the idea of combining an electron gun with a metal jet. After dinner with my family, I calculated the concept.”

The next day, the doctoral student, who was already halfway through his studies, had to change direction entirely.

“He wasn’t thrilled at first, but he managed to put a brave face on it. Later, he conducted the first experimental demonstration of the technology. It all ended well, given that we founded the company together a few years later. Research remains the most enjoyable part of my work, especially now we can see a real clinical application for the technology,” says Hertz.

Text Magnus Trogen Pahlén

Translation Maxwell Arding

Photo Magnus Bergström