Project Grant 2020

The 2D materials frontier

Principal investigator:

Professor Johanna Rosén

Co-investigators:

Linköping University

Per Persson

Fredrik Heintz

Uppsala University

Maria Strömme

Institution:

Linköping University

Grant in SEK:

SEK 29 million over five years

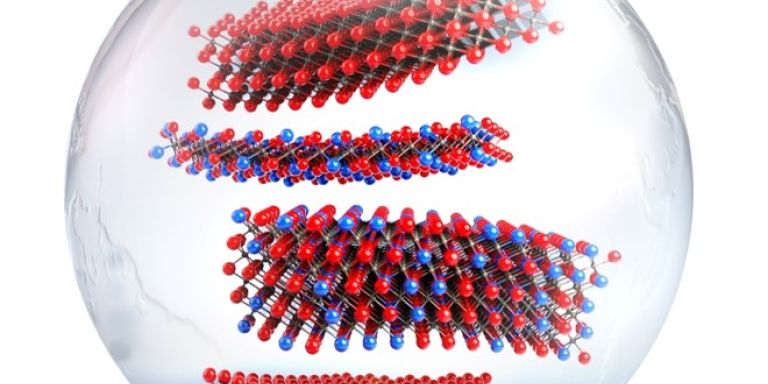

Graphene, a layer of pure carbon only one atom thick, was the first 2D material. Just over 15 years after its discovery, researchers the world over have managed to create more than a hundred ultrathin materials consisting of one or just a few layers of atoms. Most of them are made by splitting a crystal, but in Linköping another method is used. There, the scientists are using a type of material they have worked with for many years, known as MAX phases. They are made up of layer upon layer of atoms of various kinds – a transition metal interlayered with carbon or nitrogen. Johanna Rosén, who is a professor at Linköping University, describes them as sandwich cakes, from which she and her colleagues have devised a way to remove the jelly.

“We can use chemical etching to remove specific parts of the materials. We are then left with a pile of 2D materials stacked on top of each other, which are easy to separate. Carbon is the ingredient common to all the materials, but the metal can be varied, enabling us to tailor the properties of the material.”

The 2D materials produced in this way are called MXenes (pronounced “maxenes”). They were invented ten years ago, and the field continues to expand rapidly. But now there also thousands of materials that are not MXenes but are nonetheless layered. Rosén is heading a project funded by Knut and Alice Wallenberg Foundation in which researchers at Linköping and Uppsala Universities plan to ascertain which of the materials can be etched. Their hope is that those materials will become the next generation of 2D materials.

AI, super microscope and materials analysis in the same project

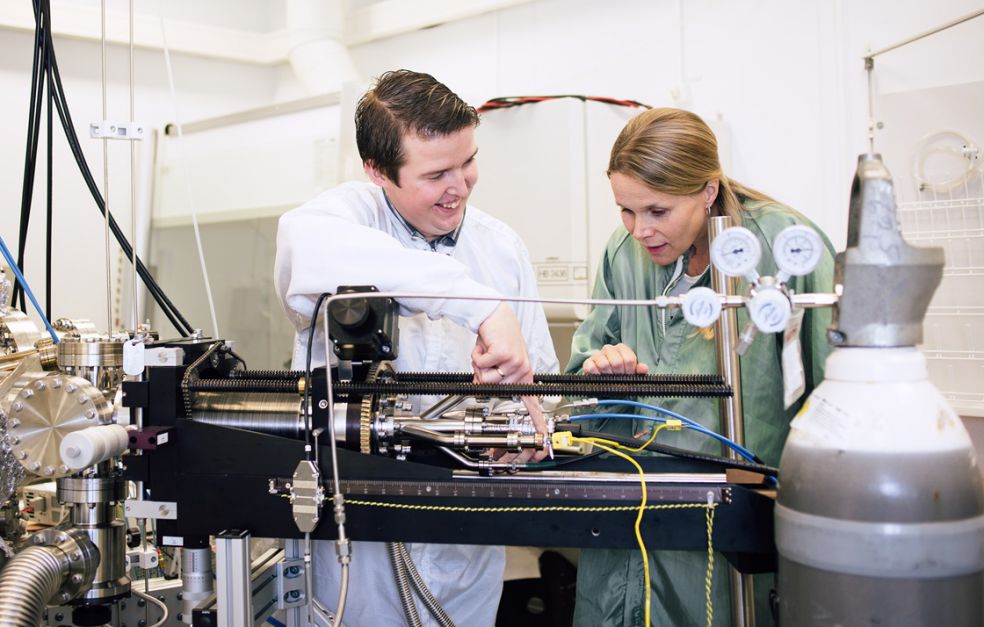

The project has three legs: advanced electron microscopy, computer science and materials analysis. Linköping’s powerful electron microscope enables the researchers to modify the materials while studying them.

“It’s really cool – we can, for example, inject gas or heat the material while simultaneously observing exactly where the atoms are placed and how stable the sample is,” Rosén says.

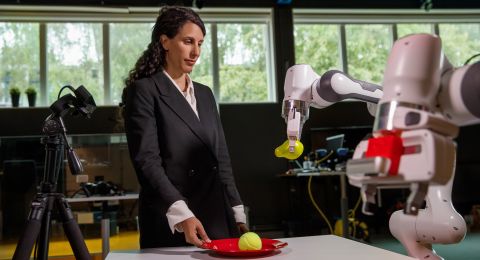

The computer science component is also based in Linköping. The idea is that machine learning and AI will enable the researchers to analyze thousands of materials in parallel, and determine which could potentially be etched into 2D form. This will require development of new methods and algorithms designed for studies of this kind. Once the researchers in Linköping have identified and managed to create a new material, it is sent to their colleagues in Uppsala for testing.

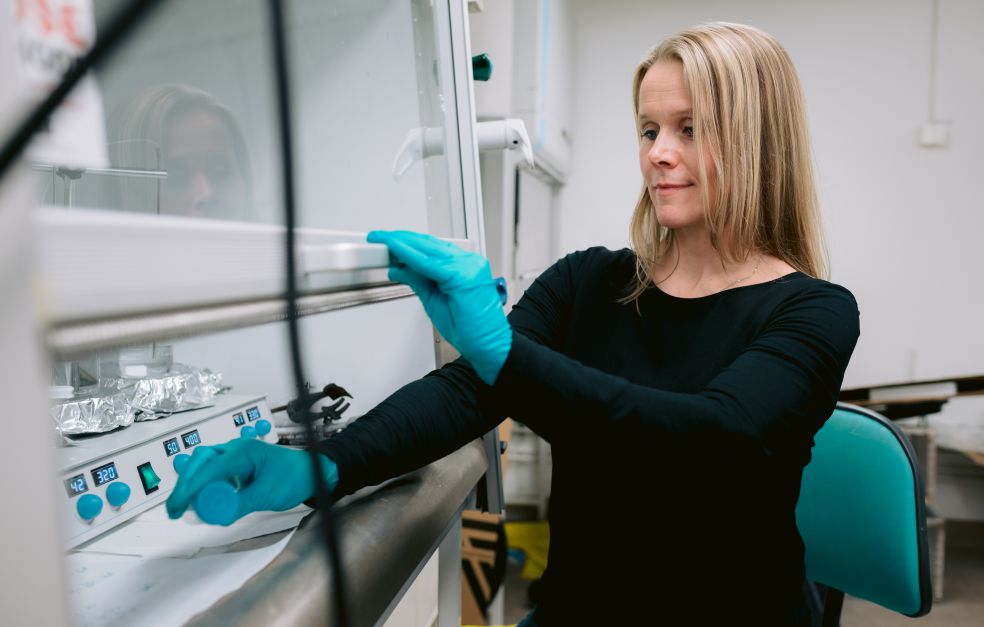

“Most of what we’re doing in the project is pure research, where we study materials and attempt to understand how different properties arise. But we also want to see how they work in practice. This is a vital part of the project – seeing whether we can in fact bring things to fruition and ensure that our materials have practical utility,” Rosén comments.

Potential uses for the materials include more environmentally friendly energy storage in batteries and supercondensers, as catalysts or in development of new drugs. Other possible applications are water treatment and desalination, where materials with a large surface area to weight ratio are needed.

Vital to find key properties

The research team has already carried out theoretical simulations to make an initial analysis of 40,000 stored materials that it might be possible to etch into 2D form. They used open databases on the internet to find several hundred thousand materials. These were then collated using the Linköping supercomputer.

“The first step is a fairly general sorting process, in which the computer eliminates materials with obviously unsuitable properties. These may be that the placement of the atoms prevents the material from being etched, or that the material is toxic, radioactive or mined in a conflict zone. Environmental and sustainability considerations must permeate everything we do.”

The team recently succeeded for the first time in using chemical etching to create a 2D material that was not a MXene.

“The competition is really tough. You can get stressed just thinking about the number of hours spent working on this in China in particular. But I hope this project will give us a leading position in this branch of materials development. We have got this far by combining theory and experiment in the same environment.”

The next challenge is to figure out the properties that are most relevant. How hard the atoms bond to each other is an initial factor, but far from the only one.

“We’ve thought a lot about this – which properties best predict whether etching will work. We can’t try etching thousands of materials. We need to have extremely good simulations indicating that a material is promising – then we can go down to the lab and spend some time on it.”

If it still doesn’t work, the team goes back to the computations. Which parameters were wrong? As they learn more, their AI tools can be fed with new information and make increasingly accurate assessments.

“We need to create models that can be generalized. When we find a new stored material, we need to be able to look at it and know whether or not it will work as a 2D material. That’s the main goal of the project,” says Rosén.

Text Lisa Kirsebom

Translation Maxwell Arding

Photo Anna Nilsen, Igor Zhirkov