Project Grant 2019

Unexplored Approaches to Organic Photoredox Catalysis

Principal investigator:

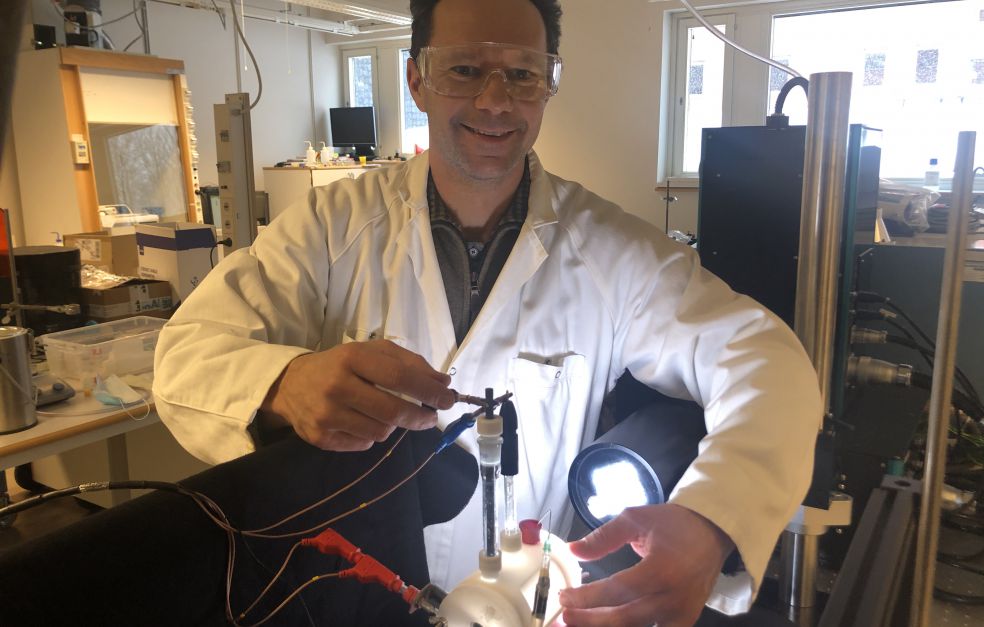

Professor Sascha Ott

Co-investigators:

Uppsala University

Eszter Borbas

Leif Hammarström

Jacinto Sá

University of Gothenburg

Carl-Johan Wallentin

Institution:

Uppsala University

Grant in SEK:

SEK 35 million over five years

Medicines, plastics, dyes, and certain types of screen and solar cells – these are examples of items in which tailor-made molecules containing carbon and hydrogen – organic compounds – can be found.

“The manufacture of organic compounds is a major and important industry. A single big-selling blockbuster drug may generate sales worth tens of billions of dollars a year,” says Sascha Ott, professor of synthetic molecular chemistry at Uppsala University.

The molecules in question are often fairly complicated. Simply put, their production starts from existing organic starting materials that ultimately originate from oil or natural gas. These molecules are then converted in several stages using chemical reagents to create the desired structure. During the process, it is necessary to break bonds between certain atoms in the molecule, and create new bonds in other places.

Energy-intensive break-ups

Breaking bonds requires a fair amount of energy, which means that the chemical reagents that are used for this purpose must be powerful and reactive. Some of them are also toxic. When the process is completed, they are left over as waste or by-products.

“The main problem with the manufacture of organic compounds is that large quantities of waste are created when the molecules are converted, and that these residual products are sometimes toxic,” Ott explains.

For this reason, chemists have long striven to make the various conversion steps more efficient with the help of catalysts, i.e. substances that accelerate the chemical reactions without themselves being consumed. This has reduced the quantity of waste dramatically in many stages, but some remain problematic. For instance, the manufacture of vitamin A produces large quantities of a troublesome residue containing phosphorus.

“More or less everyone researching in the field of organic chemistry is looking for new methods to surmount such problems,” Ott says.

And that is also the aim of the interdisciplinary project, funded by Knut and Alice Wallenberg Foundation, which he will be leading over the next five years.

Inspiration from the plant world

The idea is to convert organic compounds using light energy instead of chemicals – a project that demands cutting-edge expertise in multiple fields. Ott and his colleague Leif Hammarström, a physical chemist, have spent 15 years exploring how to capture sunlight and to convert it into renewable fuels in an artificial version of plant photosynthesis. They are now teaming up with experts in organic chemistry to see whether a similar approach can be used in the manufacture of organic compounds.

“This really is an interdisciplinary venture. None of us fully understands every aspect of the project, but collectively we possess unique expert knowledge that will hopefully allow us to succeed with our aims.”

If they do succeed, the result may be several thousand tons less waste every year.

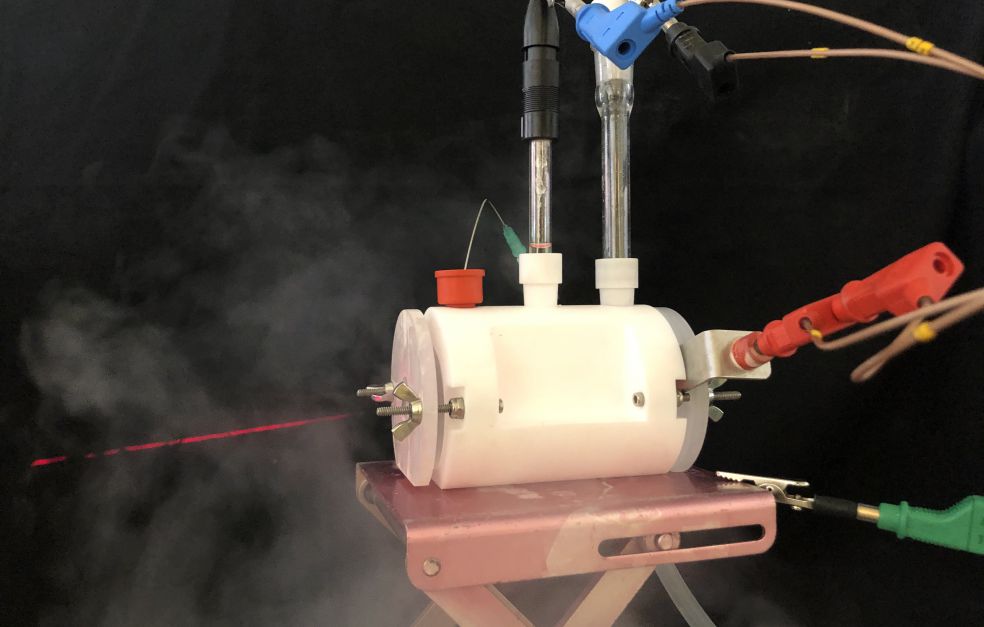

One main approach is to use a semiconductor material found in certain solar cells. When sunlight strikes the semiconductor, a high-energy electron is released. The researchers want to transfer it to an organic compound and use it to initiate a chemical reaction.

“This would enable us to manipulate the organic compound straight from the semiconductor without creating any waste at all. Otherwise high-energy reagents, often based on metal salts, would be needed to induce this type of chemical reaction,” Ott explains.

Synching quick with slow

Tight control is needed, both over physical processes such as light absorption and electron transfer, and chemical ones. One major challenge lies in matching the time scales between the ultra-fast physical processes in the semiconductor, and the much slower chemical reactions in the organic compound. Otherwise the semiconductor will reabsorb the electron before it has time to generate any conversion in the organic compound.

“Our earlier work on artificial photosynthesis taught us to delay the physical processes so the chemistry has time to do its job. That knowledge will be of great use here.”

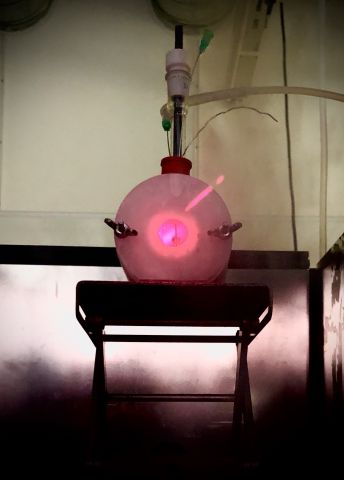

Another approach is to use “plasmonic” nanoparticles. When they absorb light, they discharge ultra-high-energy electrons. It is true to say that the challenge of unmatched time scales is even greater than with semiconductors. But the potential benefits are also greater – the very high energy of the electrons makes it possible to induce chemical reactions that would otherwise require extremely powerful chemicals.

“It’s not just about making existing steps in the organic compound manufacturing process more resource-efficient – we are trying to develop completely new ways of converting the raw materials into the end product. At present, drug manufacture usually involves many synthetic steps. Hopefully we’ll be able to find short-cuts or smarter methods with far fewer stages. If we do, there’ll be even less waste,” Ott says.

Text Ingela Roos

Translation Maxwell Arding

Photo Nina Suremann, Anna Beiler, Sascha Ott