Spider silk is one of nature’s most impressive materials, and is extremely strong and stretchable. Anna Rising and her colleagues were the first to fabricate artificial spider silk using the same mechanisms that spiders do. This may pave the way for future use in sustainable clothes and medical implants.

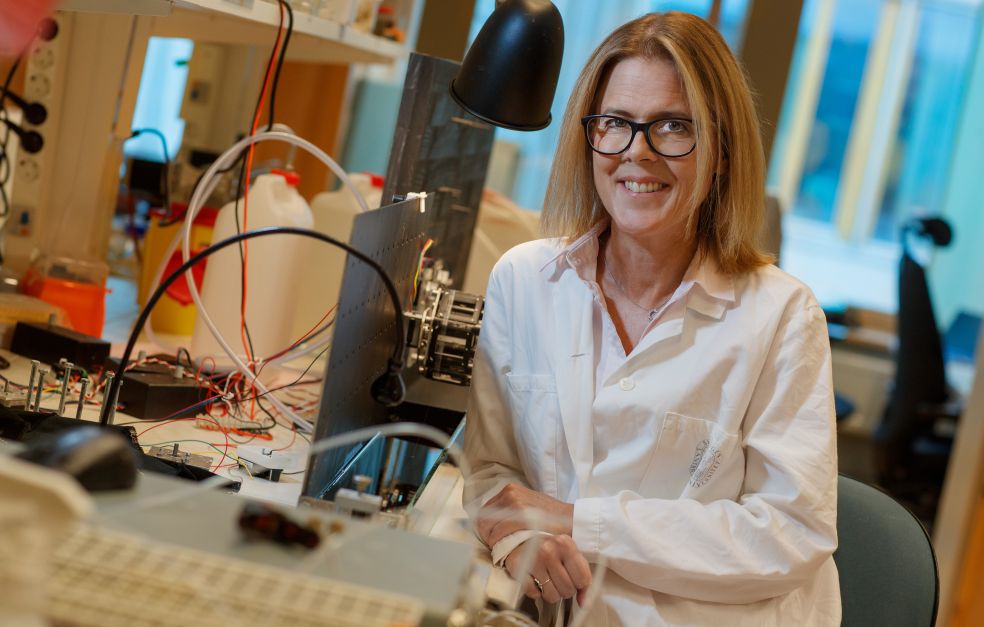

Anna Rising

Professor of Veterinary Medical Biochemistry

Wallenberg Scholar

Institution:

Swedish University of Agricultural Sciences

Research:

Biomimetics, including development of protein-based materials

Spiders have evolved over more than 400 million years, and are able to spin up to seven different kinds of silk, each possessing specific properties. One kind is the toughest fiber known, spun by spiders at lightning speed without using strong chemicals or solvents.

“Spider silk is as strong as steel, extremely stretchable and capable of absorbing more energy than any other known fiber – natural or artificial,” says Rising, who is professor of veterinary medical biochemistry at the Swedish University of Agricultural Sciences (SLU).

The properties of spider silk render it attractive for numerous applications. The research falls within the field of biomimetics – mimicking nature’s own ingenious solutions.

Hunting for spiders

As a newly qualified vet, Rising was drawn to research and had the opportunity to work on a project involving orthopedic spider silk implants.

“Spider silk is used in popular medicine to aid wound healing. It has also been found to be accepted well by the body when used in implants.”

But the project was a real challenge. Spider silk used in implants must be created artificially, and there was a lack of fundamental knowledge on spider silk genes.

To learn more about the properties of spider silk, Rising traveled to South Africa in search of a specific species of spider known for its strong silk.

“We spent several weeks in the wilds of South Africa looking for spiders among scorpions, snakes and lions. And we did in fact manage to find a hundred spiders of the species I was looking for.”

She was later able to extract DNA from those spiders and began to study the genes that code for silk proteins.

Fabrication in the lab

The next step was to transfer the silk genes to a micro-organism, in this case bacteria, capable of producing silk proteins in a bioreactor. But there was a problem: the silk proteins were sticky and formed insoluble clumps.

“And when we used harsh solvents the proteins lost their function.”

After years of research and many attempts, Anna and her colleagues managed to produce water-soluble spider silk proteins. The breakthrough came when they realized the importance of pH changes in the spider’s silk gland.

“The most characteristic feature of this gland is that pH falls from around eight to five,” explains Rising. When we realized this, we could start to study how the silk proteins behave under the conditions prevailing in the gland.”

The scientists mimicked the natural drop in pH by injecting an aqueous protein solution at pH 8 into another aqueous solution at pH 5, enabling them to spin artificial spider silk. Fabrication takes place in a purpose-built machine in the lab. The liquid is usually transparent and light yellowish, but it may also be pink or other colors if the researchers express a spider silk protein attached to fluorescent proteins.

“It’s the first time anyone has succeeded in mimicking the way spiders spin their silk.”

The moment when we could start spinning artificial spider silk in the lab was fantastic. Another milestone was when we could scale up fabrication and spin multiple threads simultaneously in a larger machine.

New insights into the silk gland

The artificial spider silk is not as strong as its natural counterpart, and Rising wants to find out why this is. In-depth studies are needed into the workings of the spider silk gland.

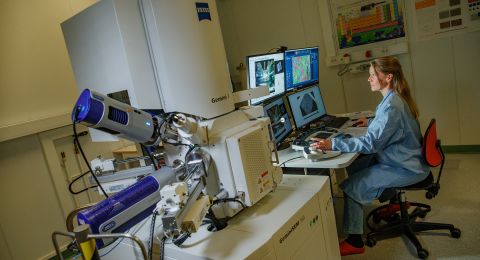

As a Wallenberg Scholar, she will be using the latest technology in the fields of sequencing, microscopy and structure determination to ascertain how the spider silk gland manages to convert a protein solution into fiber in the space of milliseconds.

She also wants to make a detailed study of the specialized cells that produce the silk protein.

“Those cells ought to have developed systems – as yet undiscovered – to be able to produce large quantities of very sticky and unmanageable proteins without them clumping together,” says Rising.

She also wants to study the relationship between spider silk protein composition and its mechanical properties. The idea is to use AI to analyze large quantities of data and find patterns that can provide new information about that relationship. AI can also be used to tailor the properties of artificial spider silk.

“We think the complex structure of the silk fibers, with layers of different proteins, is the key to their unique properties. By mimicking this, we may be able to create artificial fibers that match or even surpass natural spider silk.”

Clothes of the future

Artificial spider silk offers great potential in a number of areas. It could be used to make an environmentally friendly alternative fabric in clothing manufacture.

“Spider silk could replace plastic-based fibers, and is also renewable.”

In medicine, too, there is great potential. Spider silk can be used to help nerves to heal by providing a structure along which neurons can grow.

This research is also generating new knowledge about how to prevent proteins from clumping, which has a bearing on diseases such as Alzheimer’s and Parkinson’s.

“There is much we can learn from spiders, and we’ve just started scraping the surface of what is possible,” enthuses Rising.

Text Nils Johan Tjärnlund

Translation Maxwell Arding

Photo Magnus Bergström