Project Grant 2016

Mastering morphology for solution-borne electronics

Principal investigator:

Ellen Moons, Professor of Physics

Co-investigators:

Karlstad University

Jan van Stam

Chalmers University of Technology

Christian Müller

Ergang Wang

Linköping University

Fengling Zhang

Lund University

Ivan Scheblykin

Petter Persson

Institution:

Karlstad University

Grant in SEK:

SEK 28.75 million over five years

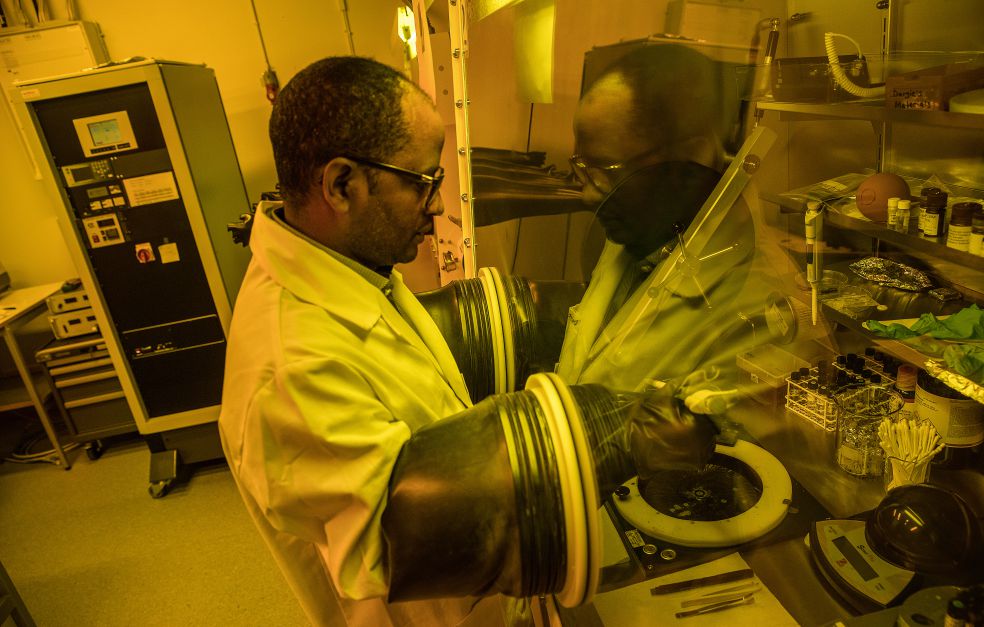

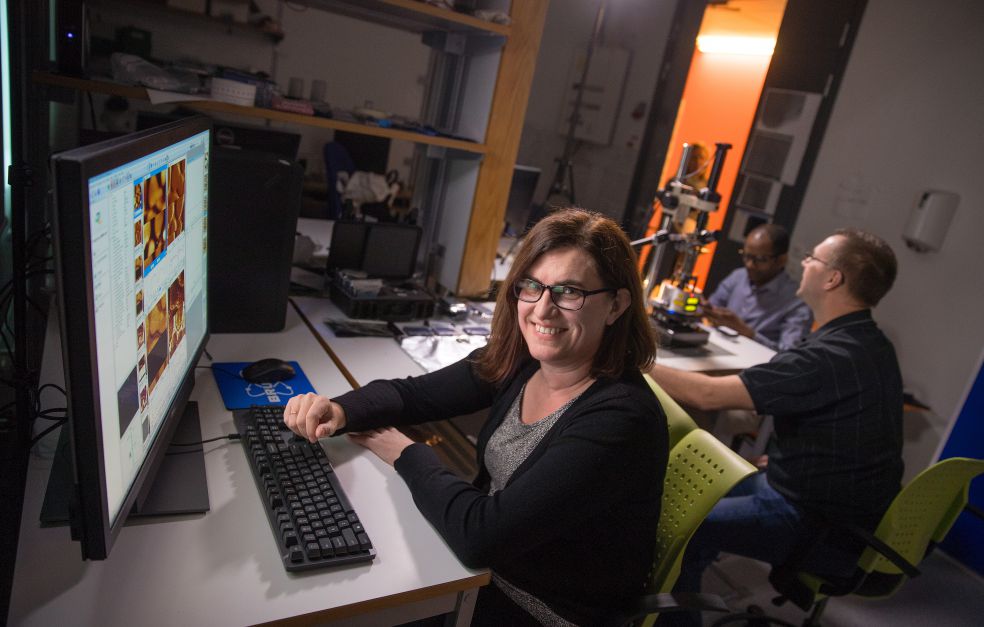

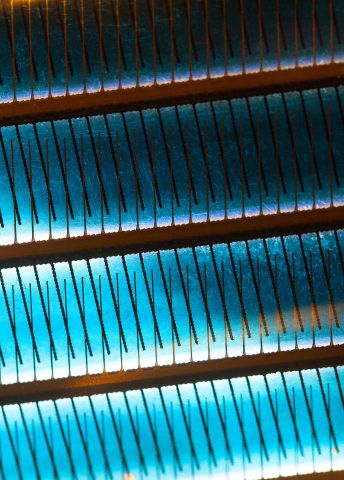

The lab at Karlstad University is a hive of activity. A long-awaited upgrade is being made of an atomic force microscope (AFM), used to carry out nanoscale studies of polymer solar cells. A nanometer is one billionth of a meter. Images from the microscope give the researchers information on the properties of the material. Like a phonograph, the microscope uses a sharp probe to scan the morphology – structures – in the photoactive layer of the solar cell, where light is absorbed.

“Really good resolution – it’s never looked this good before,” exclaims Moons, who is a professor of physics, when she looks at the computer screen.

The upgrade has been made possible by a five-year project grant from the Knut and Alice Wallenberg Foundation. Moons’ project also involves researchers from Chalmers University of Technology, Lund University, and Linköping University.

“The ultimate purpose of the project is to create polymeric solar cells that can be made cheaply. We want to make them more efficient and more stable. We’re focusing on solar cells because that’s where our experience lies, but the principles at the heart of the project can essentially be applied to other polymer electronics, such as LED.”

The drying process

Moons explains that polymers consist of long chains, mainly of carbon atoms. Solar cells based on light-absorbing and electrically conducting polymers may offer an alternative to current silicon-based units. But to be more commercially viable they need to be more efficient, and have a longer life.

A solar cell with the right characteristics and performance is created by mixing the polymers in a solution, which is then applied to a surface such as glass or flexible plastic. The photoactive layer contains molecules that are electron donors and acceptors. Moons and her fellow researchers want to know more about how they are mixed. They are finding out with the help of physics, chemistry, and electronics.

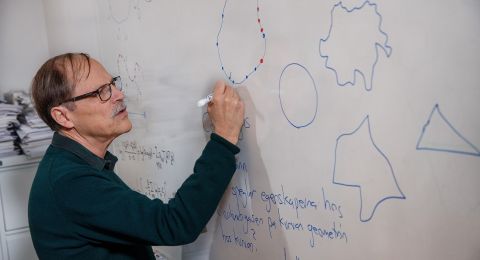

“The solvent evaporates and during the drying process the distribution of donor and acceptor molecules changes, it phase separates. We want to know how this happens, and how we can control phase separation to achieve a specific morphology in the photoactive layer. We have decided to study a specific kind of polymer solar cell – a polymer-polymer solar cell, in which both donor and acceptor are polymers. All teams involved in the project will be focusing on the morphology based on their specialized methods.”

Refining information

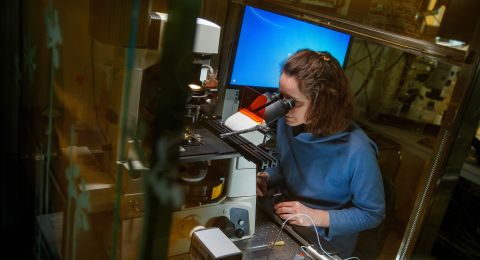

Most of the researchers’ work involves experiments. Different types of advanced microscopy and spectroscopy methods are used, depending on the size of the structures in the photoactive layer.

“One major challenge is to find the right method so we can see what happens during the drying phase. It’s a dynamic process – we want to be able to image it, and extract information on the morphology at as high a resolution as possible,” Moons says.

The grant will also be used to purchase a new instrument, known as AFM-IR, which combines atomic force microscopy with infrared spectroscopy.

“It will be the first one in Sweden. So when we examine the structure using the thin probe scanning the surface, we will also be able to use an infrared beam to extract information about which molecules are present in the photoactive layer. We can see which molecules are there, more or less as we can when we use X-ray spectroscopy at synchrotron light source facilities, which entail lengthy journeys for us. We will soon have this technology here in Karlstad.”

Greater knowledge of the drying process in the photoactive layer is needed to achieve the ultimate goal of larger-scale production of polymer solar cells, using special printing methods. Moons shows an example of a printed solar cell she has received from fellow researchers at the Technical University of Denmark.

“To manufacture large flexible polymer solar cells using roll-to-roll printing, you must know how this layer dries. We haven’t printed any solar cells yet. Since we are working on fundamental questions, we usually coat them on a rigid substrate that is suitable for our measurements. So far we have made solar cells on glass, but the same technology can be used on flexible substrates like plastic.”

As part of the project, researchers at Linköping University are developing printed polymer solar cells in collaboration with a spin-off called Epishine in Norrköping.

Established collaboration

The project has its roots in a long-running collaboration on organic solar cells, principally between Linköping, Lund, and Chalmers universities. The research teams will include PhD students who will be supervised jointly. Moons comments:

“It’s wonderful – it means a great deal to receive this grant. For me as a researcher and for us in Karlstad, but most of all because it secures long-term continuation of our successful collaboration. We can build on something we’re good at in Sweden.”

Text Susanne Rosén

Translation Maxwell Arding

Photo Magnus Bergström