Can carbon dioxide become a raw material for producing plastic? Researcher Jiayin Yuan hopes so, as he develops a method to replace current oil-based raw materials with carbon dioxide to achieve significant climate benefits.

Jiayin Yuan

Professor of Materials Chemistry

Wallenberg Academy Fellow prolongation grant 2022

Institution:

Stockholm University

Research field:

Materials chemistry and processes to mitigate the effects of climate change

Carbon dioxide is a colorless gas that plays a vital role in photosynthesis, forming the basis of biological life on Earth as we know it. Carbon dioxide is also a greenhouse gas, however. Rising levels of this gas in the atmosphere contribute to global warming and climate change.

To reduce the amount of carbon dioxide in the atmosphere, various countries plan to capture and store it. But the ideal solution is not to only store collected carbon dioxide, says Yuan, professor of materials chemistry at Stockholm University:

“It’s better to find good ways to use and consume it immediately, like trees in a forest do as they grow.”

Having explored the possibility of using carbon dioxide as a raw material for eco-friendly fuels, he and his research team are now studying whether it is possible to convert carbon dioxide into a monomer precursor for plastic.

More than 380 million metric tons of plastic made from fossil oil are produced globally each year, and the processing of oil products used in plastics – not least the burning of plastic waste – contributes to negative climate impacts such as drought, extreme weather, and heat waves due to carbon dioxide emissions.

Developing fossil-free plastic

One of the world’s commonest oil-based ingredients in plastic is ethylene. Ethylene is produced from fossil resources industrially, forming long chains of carbon atoms, known as polymers, and is referred to as polyethylene in its final form. Yuan explains:

“We want to find a way to make fossil-free ethylene plastic to reduce climate impacts.”

Yuan was born and raised in Shanghai, China, which he later left to study and conduct research at prestigious institutes and universities in Germany and the U.S. There, he researched new porous carbon membranes and activated carbon, among other topics.

In 2018 he accepted an offer to work as a researcher at the Department of Materials and Environmental Chemistry at Stockholm University, where he became a professor a year later. He is the director of the “Stockholm Material Hub”, a network bringing together materials researchers in universities and in industry.

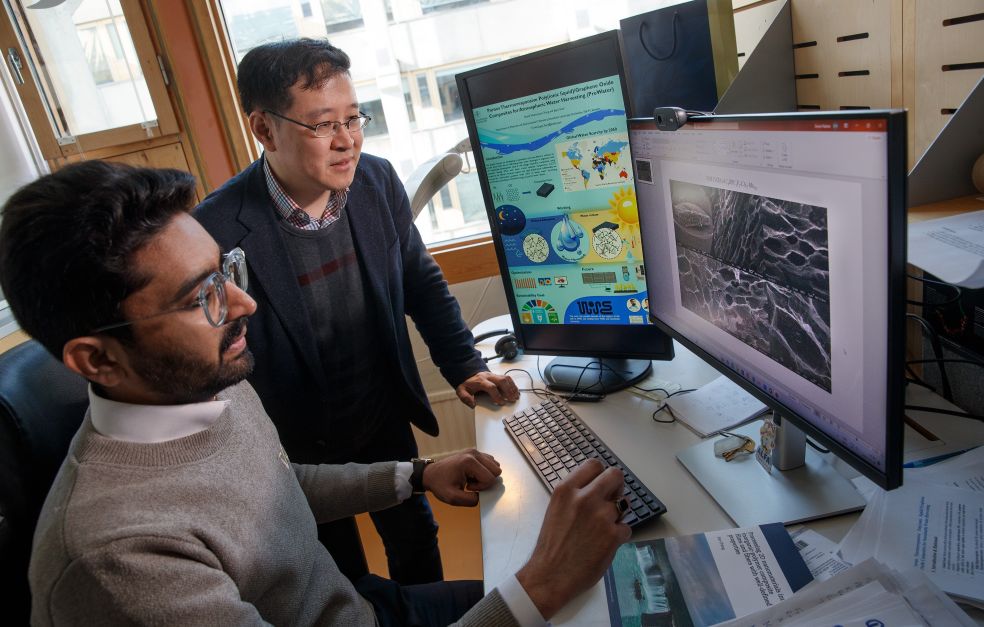

As a Wallenberg Academy Fellow, Yuan is leading a project called CatchCO2, which aims to develop a method of converting carbon dioxide into ethylene.

“If we succeed, our method could significantly reduce the use of fossil raw materials in the chemicals industry and reduce the world’s dependency on oil-based raw materials.”

The researchers are also working on two other major related research projects involving the separation and capture of carbon dioxide.

Reducing climate impacts

Yuan is keen for the project to achieve multiple climate benefits.

“The idea is to use carbon dioxide to produce fossil-free ethylene, a monomer precursor to polyethylene. This not only reduces atmospheric carbon dioxide but also the carbon footprint created by producing fossil-based plastic. We aim to use renewable electric energy in our conversion process, and we hope to find an effective way of recycling the polymers.”

The ideal solution is not to only store collected carbon dioxide. It’s better to find good ways to use and consume it immediately, like trees in a forest do as they grow.

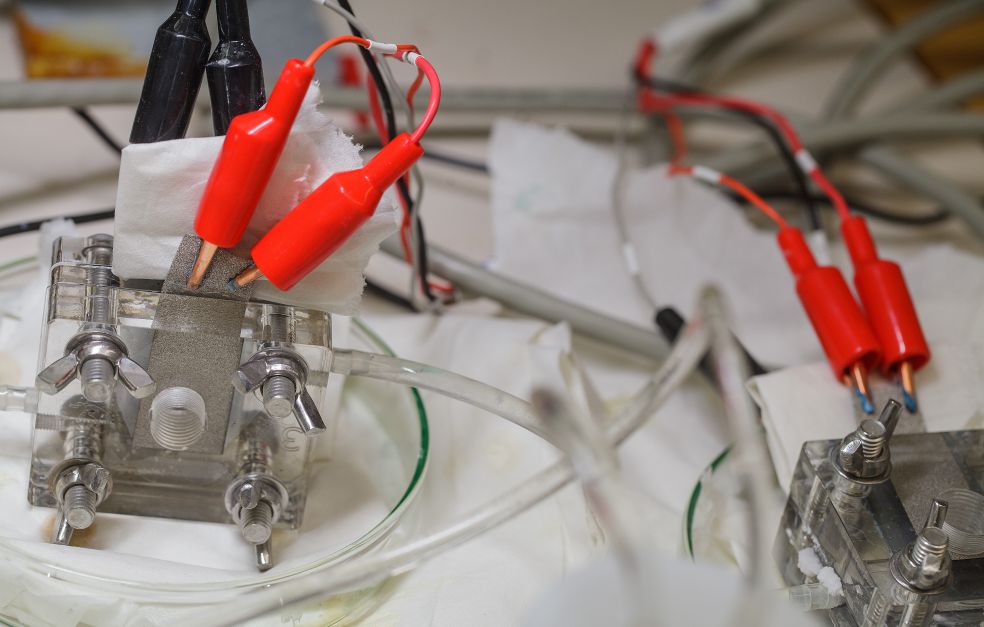

The core of the CatchCO2 project is the design of a new generation of metal/carbon membranes, which the researchers are currently testing on a small scale as a means of converting carbon dioxide into ethylene gas.

In the experiments, the membrane is placed in a flow cell reactor containing water, and connected to an electric current via an anode and a cathode. Carbon dioxide gas is pumped into the flow cell through a tube, and ethylene gas flows out on the other side.

A continual electrochemical process takes place in the flow cell, reducing the carbon atoms in the carbon dioxide, and splitting the water into hydrogen gas.

The process is still being refined. Among other things, the researchers are testing which metals work best as catalysts for the reaction. These include copper and various alloys. It is crucial that the metal atoms are dimensionally confined, less than two nanometers across, and positioned on the surface of an electrode. These specially designed molecular structures allow the researchers to fine-tune the process and ensure that ethylene – and not other carbon compounds – is formed.

Scaling up essential

Another goal for Yuan’s team is to design and test the CatchCO2 model for future industrial use. One way of achieving this could be to place hundreds or thousands of flow cells together to produce large quantities of fossil-free ethylene gas.

There are challenges in scaling up the model. One is to harmonize the electrical conditions in the flow cells with the technical production requirements.

But Yuan enjoys solving tough problems.

“I am living my dream. Being able to research and teach science is something I’ve wanted to do since childhood.”

Text Monica Kleja

Translation Maxwell Arding

Photo Magnus Bergström