Strategic initiatives

Wallenberg Wood Science Center, WWSC

WWSC is a joint research center operated in collaboration between KTH Royal Institute of Technology, Chalmers University of Technology and Linköping University.

The Center was founded in 2009 with the aim of developing new materials from Swedish forests, as a complement to traditional products such as timber, pulp and paper.

Website:

WWSC

Grant:

A total of SEK 1.2 billion 2008–2028

In addition to funding from the Foundation, Swedish forest-product companies and the universities involved have allocated funding totaling over SEK 300 million.

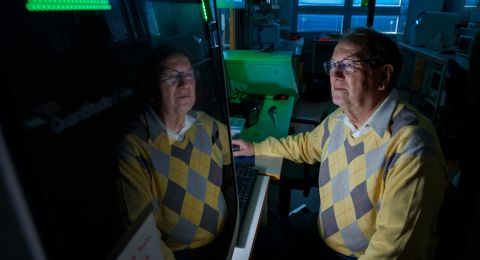

“WWSC researchers and research initiatives have helped to revolutionize how we can use wood-based raw materials to create completely new materials, and also as-yet-unidentified future materials,” Eva Malmström Jonsson says without hesitation.

“And we have achieved this by understanding the materials at molecular level,” she adds.

Eva Malmström Jonsson is Director of WWSC and Professor in Coating Technology, or “plastics researcher,” as she puts it.

WWSC was founded in 2009 for the purpose of developing new materials from the Swedish forest. Ideas include creating stronger and flame-resistant materials, porous materials, new materials for energy storage and bio-based electronics, and replacing oil with wood-based raw materials in the manufacture of plastics. The research has already borne fruit in the form of paper that is magnetic, conductive, and fire-resistant. The sustainability dimension has gradually come to occupy center stage.

Bio-based wood glue that is both non-toxic and biodegradable, batteries made of paper, and an entire computer based on raw materials from wood – all these are potential applications of research at WWSC, where use is being made of the three constituents of wood: cellulose, hemicellulose and lignin.

Bio-based “plastics”

Traditionally, only the cellulose has been utilized, but this is something researchers at WWSC are attempting to change.

“Wood is a fantastic material – the product of evolution over millions of years. Now when it is possible for example to divide the cellulose fibers up into nanofibrils, many new properties can be realized. Creating new materials by disassembling and removing components from the tree trunk as efficiently as possible without breaking them down too much is the focus of the first of our five programs.”

Plastic – once considered a wonder material – is now regarded as a problem, not least for the environment, since it is not biodegradable.

“Each year 380 million tons of plastic is produced throughout the world, but only two percent comes from bio-based raw materials,” Malmström Jonsson points out.

She explains that the first attempts to find bio-based materials were based on creating exact copies of the building blocks of fossil counterparts.

“But now we want to understand nature’s own molecules and modify them. The aim is to obtain the same properties as the fossil counterparts, but not necessarily with the same chemical structure. It’s the function we’re interested in, and creating materials that can be recycled.”

Lignin and hemicellulose, which nearly always used to be burnt as a by-product, are now at the center of research program number 2, whose goal is to replace disposable materials with wood-based substitutes.

“Wood is an incredibly important and exciting resource for a sustainable future, since wood-based materials have great potential as substitutes for fossil-based materials. They can also form the basis for completely new materials with new properties,” says Eva Malmström Jonsson, Director of WWSC.

Cellulose-based electronics

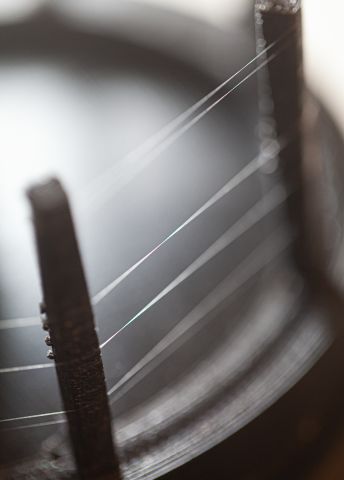

The third program focuses on fibers and nanofiber technology, which is where the “steel fibers” come in.

“Our greater understanding of the molecular processes and nanocellulose – how it can be used and tailored, enables us to develop new materials.”

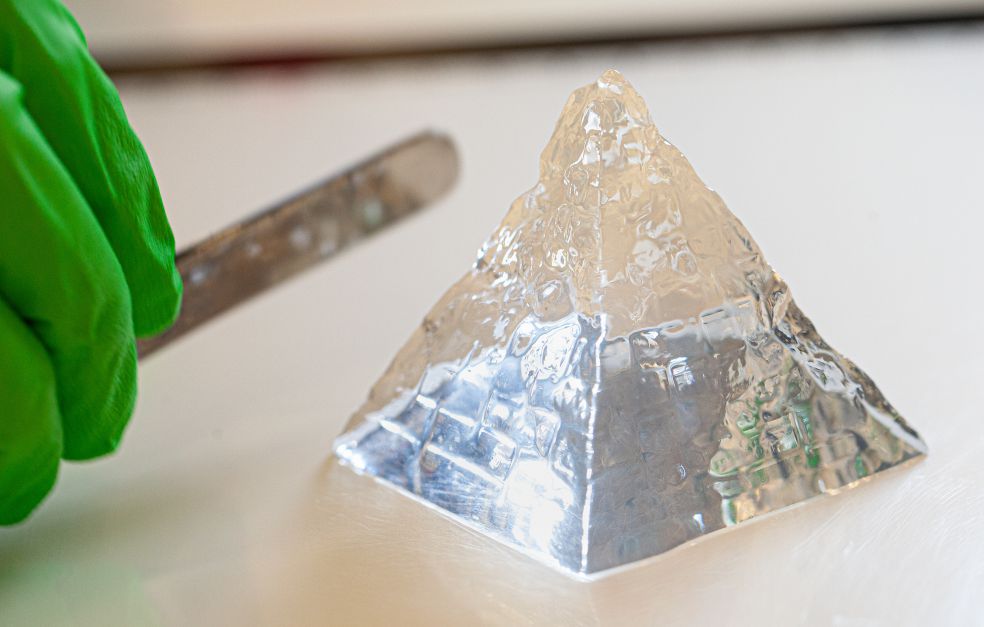

As an example, she mentions “solid water,” where nanocellulose structures lend solid form to a material that consists of 99 percent water.

“Nanocellulose is a really exciting material, with a broad property window. It can, for instance, be tailored to be superabsorbent, rendering it highly suitable for use in diapers for example. It can also be bonded together in an aqueous process, creating the world’s strongest biofibers – stronger than steel. Again, it’s necessary to understand the molecular processes. It’s another example of fundamental scientific research that may be of benefit to many with a modicum of further development.”

Program number four is using wood-based materials for applications in the fields of energy and electronics.

“Bio-based carbon and nanofibrils are used as structures and functional carriers, and lignin has been found to possess chemical properties that are suitable for chemical reactions.”

One vision, albeit one that is some way off, is to create a computer from these components.

“This is of enormous interest, given that so much of modern electronics consists of materials that are scarce.”

Other aims of this program are to generate electricity, purify water, and create batteries largely made of cellulose.

Nothing goes to waste

The fifth program is concerned with biocomposites, and spans a broad spectrum from fairly simple materials to advanced ones. One project is attempting to generate electrical energy, but the idea that has so far attracted most attention is to create transparent wood. It should be possible to scale up production before too long so that the material can be used for construction purposes.

Malmström Jonsson summarizes the five programs in just a few words:

“It’s a question of ensuring that when we chop a tree down, we use as much of it as possible. Wood possesses fantastic properties and offers huge potential for building a more sustainable future. We have a vision of being able to reuse the fiber 100 times before it becomes unusable. Nothing must go to waste.”

The UN global sustainability goals are central to research at WWSC.

“Just because you use bio-based raw materials doesn’t mean for sure that the product and its manufacture are sustainable.”

Despite all the exciting research in progress, Malmström Jonsson starts by highlighting something else when she talks about WWSC.

“The jewel in the crown is our graduate school – WWSC Academy. Much of the work we do is in the hands of the PhD students at the universities, who possess expertise in different parts of the field. They contribute to the dynamic environment, our innovativeness and our international profile. The 60 PhD students who have received their PhDs while with us provide a real boost to our expertise – both in academia and industry, and play a part in the formation of new companies.”

Text: Carina Dahlberg

Translation: Maxwell Arding

Photo: Magnus Bergström

Facts about wood

Wood is made up of cellulose, lignin and hemicellulose.

At present only half of the wood – the cellulose – is normally put to use. Most of the remainder is burnt.

About 30 percent of wood comprises lignin. Lignin is an aromatic carbon compound that has largely been used as an energy source through combustion. Lignin may also become a key component in bioplastics and in use for energy storage.

The third principal constituent of wood – hemicellulose – is often water-soluble, which can create problems in the manufacture of materials. But the researchers at WWSC are attempting to convert the hemicellulose so it will be easier to use.