Wallenberg Initiative Material Science for Sustainability – WISE

Research on sustainable materials, manufacturing processes and circularity – reuse.

Host University:

Linköping University

Partner Universities:

Chalmers University of Technology, KTH Royal Institute of Technology, Lund University, Stockholm University, Uppsala University, Luleå University of Technology

Funding:

SEK 3 billion (2022–2033)

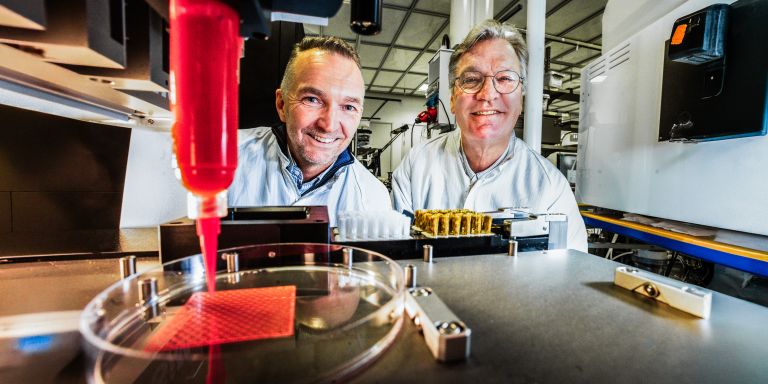

So say Magnus Berggren, Program Director, and Olle Eriksson, Deputy Program Director for the Wallenberg Initiative Material Science for Sustainability (WISE).

“Although materials are the main reason our society has a negative environmental impact, they are also our most important tool for solving the problem,” says Magnus wryly, adding that it was originally Olle who put it that way.

The two research leaders are in sync, often anticipating each other’s ideas or quoting one another as they meet to discuss the program, which was launched in 2022.

At that time, although Sweden already had a strong materials research community to build on, the sustainability dimension had not been a defining or unifying feature – either in Sweden or elsewhere.

Running out of time

Knowledge of new materials and their production have advanced humanity and our societies throughout history – from bronze and iron to the semiconductors that paved the way for our modern digital world. But many of the materials use and the way they are mined and produced have also contributed to today’s environmental problems, much due to a lack of sustainable thinking.

The numbers speak for themselves. Every year 100 billion tons of raw materials are extracted globally – mainly metals, minerals, fossil resources and biomass – to produce a variety of materials. This number is set to double by 2050. Most of the materials extracted are non-renewable resources, putting great pressure on the environment, society and climate. Global production of materials accounts for around 25 percent of total greenhouse gas emissions; metal production alone consumes about 8 percent of all the energy we generate.

“Every five seconds we produce enough plastic to wrap around the entire Eiffel Tower, and in one hour we make enough iron and steel to build 20 new towers,” says Eriksson, quoting examples from a book by Ed Conway.

Reducing the environmental and climate footprint of the materials we use in everyday life and industry is necessary to achieve global climate and environmental goals – and time is short.

“We don’t have time to wait until every last detail has been researched. As scientists, we often think there’s always more to study before moving on to applications – but we no longer have that time. We now have to do everything in parallel: conduct basic research, think about applications and move toward innovation. It’s a huge challenge,” says Berggren.

“Without, of course, compromising scientific quality,” Eriksson adds.

Collaboration with Swedish industry

They also emphasize that the program’s research arenas – called WIRA – which are run in collaboration with several industrial companies, along with industry-sponsored PhD students and postdoctoral researchers within the program, have a crucial part to play.

“This approach enables us to learn from each other. We gain access to real-world problems we might not otherwise have known about, and we have the opportunity to quickly bring our results to industry. This can shorten timelines and further enhance the potential for innovation.”

Some 40 Swedish companies are involved in the program in various ways.

“What’s so exciting and important is that it’s not just a small corner of industry – the program is broad, spanning everything from steel and electrification to production,” says Olle Eriksson.

Another example they mention is Knut and Alice Wallenberg Foundation’s proof-of-concept grants.

“These grants give researchers an opportunity to demonstrate that a scientific discovery can be scaled and utilized by society – the research needed before it becomes investable and ready for commercialization,” explains Berggren.

Although industrial collaboration is an important part of the program, the main focus remains on basic scientific research and knowledge-building, particularly within the program’s graduate school.

“It’s gratifying that we manage to attract young researchers from all over the world, and roughly equal numbers of women and men.”

The program is unique of its kind, even by international standards – no other program can rival the scope and breadth of WISE.

“We have engineers, materials scientists, chemists, physicists, all disciplines within materials science, and for materials of all kinds. It’s unique,” they point out.

Another key aspect is access to computational capacity and the Berzelius supercomputer.

We hope the WISE program can inspire others, not only in Sweden but also internationally.

Examples of ongoing research projects within the program include replacing insulation materials such as polystyrene and fiberglass with a cellulose-based material, developing more sustainable and recyclable concrete, and finding ways to replace rare earth elements used in magnetic materials, such as those needed for wind turbines.

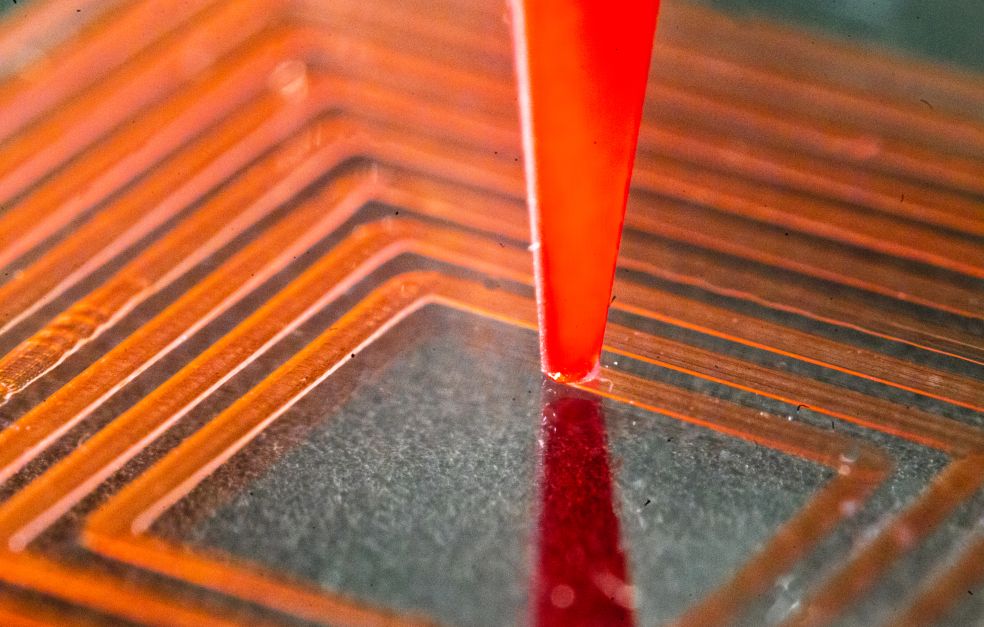

“The research isn’t just about finding new materials but also about developing sustainable manufacturing methods and creating circularity through recycling and reuse,” Eriksson explains.

Even though human extraction and production of materials are contributing to the current crisis, Olle and Magnus believe that materials are also the solution.

“Sustainable materials research is crucial to reversing this trend. The drive and energy we see within the WISE program – both among researchers and in industry – give us hope,” they conclude.

Text: Carina Dahlberg

Translation: Maxwell Arding

Photo: Thor Balkhed

Facts WISE

The program focuses on four areas of basic research:

- Conversion, storage and distribution of clean energy

- Replacing rare, energy-intensive and toxic materials with circular, sustainable ones

- Preventing pollution and purifying and protecting the atmosphere, soil and watercourses

- Promoting the discovery of entirely new materials for the sustainable technologies and applications of the future

Three research arenas:

- WIRA-SET (Sustainable Electrochemical Technologies)

Aims to find replacement materials for PFAS – toxic, non-degradable substances found in electronics and construction materials – and to reduce the use of critical materials in electrochemical processes. - WIRA–SUPRA

Developing replacement materials and circular methods for polymer materials in bulk and structural plastics, including those used in trucks. - WIRA-WATERWISE

Emphasis on the interaction between water and fibrous materials to create improved construction materials, packaging and high-energy components.