Wallenberg Academy Fellow Zhen Zhang is enlisting the help of silicon chip technology to develop a new type of miniature laboratory with great biomedical potential. A single biochip contains many nanoscale electronic sensors for parallel analyses. The technique offers new scope for exploring living bio-system down to molecular level, with potential for better development of therapeutics in the future.

Zhen Zhang

Professor of Electrical Engineering

Wallenberg Academy Fellow, prolongation grant 2020

Institution:

Uppsala University

Research field:

Nanoscale electronic biosensors for biochemical analysis

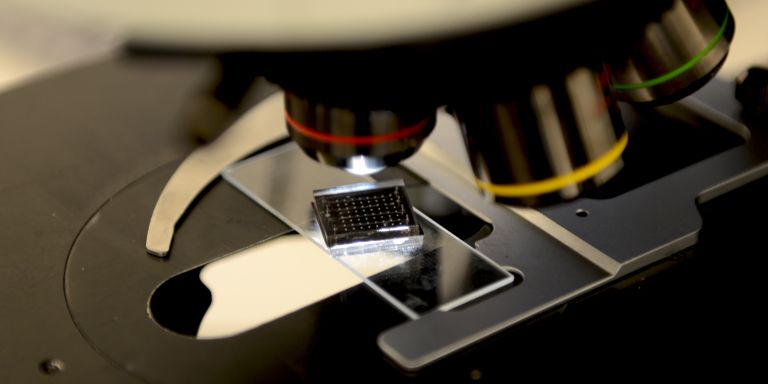

Over the past few years Zhang and his research team at Uppsala University have established an advanced platform that enables them to fabricate biochips containing nanoscale electronic biosensors. The biochips are made of silicon, a material associated with the burgeoning information society.

For several decades now strenuous efforts have been made to make silicon components ever smaller and ever faster. Billions of identical silicon components can now be accommodated on a chip no bigger than a fingernail. But we are at the same time reaching the fundamental limits of size miniaturization. Zhang elaborates:

“We’re getting to the point where researchers need to think about the next step – how we can take advantage of this enormously powerful technology and develop new applications.”

Zhang’s biochips work like miniature laboratories in their own right, where the integrated nanoscale silicon components are used directly as electronic biosensors instead of supporting electronics in traditional biosensing instruments. They hold potential to greatly reduce the cost and boost the efficiency for biosensing.

“We’ve spent a great deal of time and effort developing and fine-tuning the technology, an initiative that wouldn’t have been possible without the funding provided by Knut and Alice Wallenberg Foundation.”

“The Wallenberg Academy Fellow grant is crucial for me as a researcher. It is a major endorsement, and provides robust, long-term funding. It is also a great advantage to get to know prominent researchers in Sweden via the Fellow network.”

Zhang’s team has also established a laboratory in which the researchers are testing and evaluating the biosensors. Parallel analyses can be carried out with extremely high efficiency on the tiny surface of the biochip.

One important initial approach was to study and understand the interactions between biosensors and liquid samples, which enabled reliable detection of different charged particles, e.g. different ions in chemical and biological samples.

The team is now focusing on various biomedical applications. One project, funded by the Swedish Research Council, is using the nanoscale biosensors to monitor bacterial metabolism for rapid testing of antibiotic susceptibility.

Analyzing individual molecules

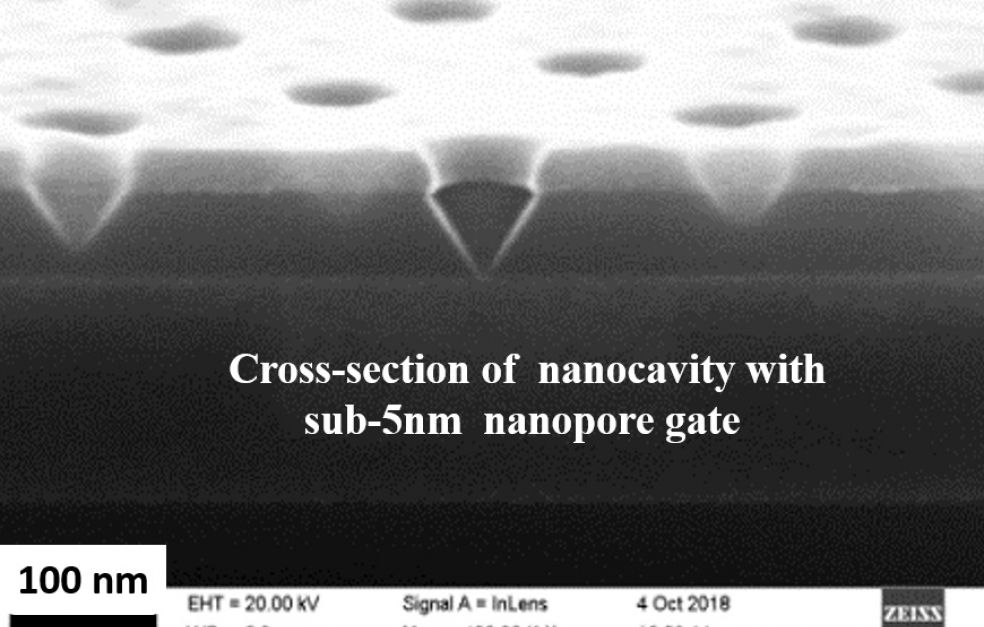

Another project included in the Wallenberg Academy Fellow grant aims to achieve what no one has yet managed in the scientific literature. Zhang and his colleagues want to use silicon technology to create a defined nanoscale environment in which they can analyze individual molecules.

“Currently available instruments normally analyze whole groups of biomolecules in a buffer fluid, which provides information in the form of average values. But we know little about the behavior of individual molecules.”

The researchers are building miniaturized silicon reaction chambers on the biochip. Nanoscale “gates” lead into the chamber. Single molecules can be dragged into the chamber through the tiny gate by electrical force. An electrical blockage signal will be generated when a molecule is dragged through the gate, which can act as a real-time feedback to enable controllable single molecule capturing.

“The aim is to achieve a completely new fundamental understanding of living bio-system at the single molecule level,” Zhang says.

But a number of challenges remain. One difficulty is how to ensure that the captured molecule continues to move freely in the chamber, without getting stuck on the surface.

“There’s a fair amount of surface chemistry that we need to understand and design in the right way. Our research is based on interdisciplinary collaboration, and we’re also being helped by other research teams at Uppsala University, as well as specialists at other institutions such as KTH Royal Institute of Technology and Karolinska Institutet.”

Prospect of better drugs

If the project succeeds, it would represent a scientific milestone, with repercussions for fields such as biomedical research. But Zhang also sees other potential applications – in the pharmaceutical sector, for instance. There is a great deal of interest in more exact measurements and analyses of proteins for therapeutics.

“It might be possible to make a high-precision study of how drug and receptor interact at single molecular level, and even to create environments that resemble the cell plasma.”

One advantage of silicon technology is that it is easy to scale up fabrication to mass production, provided the efficacy of the method can be verified.

Zhang enjoys life as a researcher in Sweden. He first came here in 2003, as a PhD student at KTH Royal Institute of Technology in Kista. After receiving his PhD in 2008, he worked for more than five years on advanced chip technology at IBM’s research center in New York, where he acquired an insight into the needs of industry, and a valuable network of contacts.

In 2013 he was awarded the Ingvar Carlsson Award, and returned to Sweden, this time to Uppsala University. He has built up his research there from scratch, as he puts it, and is grateful for the Wallenberg Academy Fellow grant, which provides long-term funding.

“We have been given the financial resources to build this technical platform from scratch, and gather the unique skills and knowledge possessed by the members of our team in Uppsala.”

Text Nils Johan Tjärnlund

Translation Maxwell Arding

Photo Zhen Zhang, Shuangshuang Zeng, Yuan Zhu, Mikael Wallerstedt