Project Grant 2014

The tail of the sun

Principal investigator:

Xavier Crispin, Professor of Organic Electronics

Co-investigators:

Martijn Kemerink

Magnus Berggren

Mats Fahlman

Igor Zozoulenko

Olle Inganäs

Weimin Chen

Institution:

Linköping University

Grant in SEK:

SEK 33.6 million over five years

There are now just over seven billion people on Earth. That figure may reach ten billion within a mere 30 years. But the growing population brings a growing need for electricity and heating. Meanwhile, we face global warming due to carbon dioxide emissions from fossil energy sources. This is no easy equation, but luckily, we have access to an inexhaustible and renewable energy source: the sun.

“Solar energy offers enormous potential. But we also need to make use of invisible infrared rays, something that current silicon solar panels cannot do,” says Xavier Crispin, who is Professor of Organic Electronics at Linköping University, Norrköping campus.

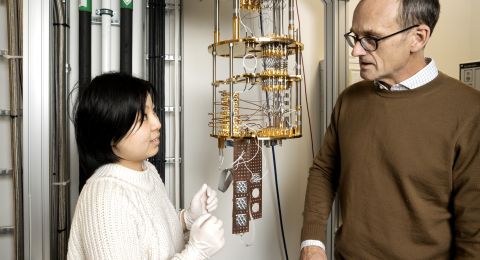

Driven by the global energy challenge, he has put together a “dream team” of seven successful research groupings in the field of organic solar panels and electronics. Everyone in the teams comes from Linköping University, and is used to working together. With the help of funding from the Knut and Alice Wallenberg Foundation, they have joined forces to develop a new solar panel component capable of capturing infrared rays.

Catching the tail of the sun

Xavier calls the invisible part of the solar spectrum “the tail of the sun”. He shows a colorful graph.

“Half of the sun’s energy is found in the invisible IR tail. It is that energy we want to harness.”

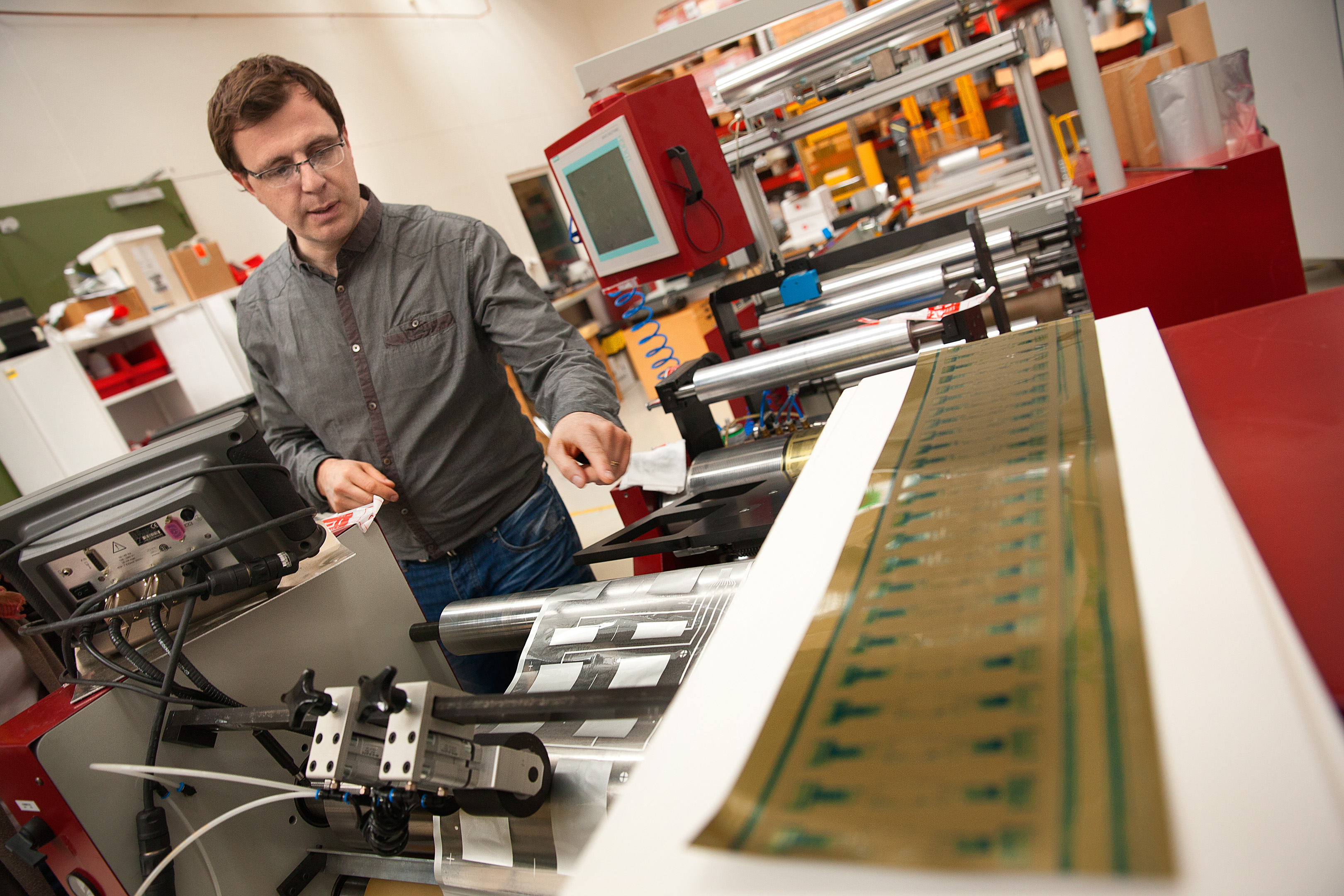

Organic solar panels are often called plastic solar panels, since their electronic components are made from organic polymers. In liquid form, the polymers form a kind of “ink” that can be printed on paper and other media. Plastic solar panels are not yet on the market, but major companies in Germany and elsewhere are commercializing the technology.

One great advantage is that they are thin and flexible; another is that they can be made from inexpensive and recyclable materials. Organic solar panels also require less energy to produce than normal silicon solar panels. This reduces the unit cost when large quantities are made. Mats Fahlman, who is a professor of surface physics and chemistry, explains:

“The idea is to improve existing technology by adding an IR-capture component.”

Mass production cheaper

Other solar panel materials and technologies are highly promising and efficient in the IR spectrum. One example is CIGS solar panels, where the light-absorbing layer is a composite of copper, indium, gallium and selenium.

“Unfortunately, indium, gallium and selenium are finite natural resources. It is not possible to make solar panels out of these materials that are large enough to meet future energy requirements,” Xavier points out.

The drawback with organic solar panels so far has been their low efficiency, and their short life span; the organic materials are generally broken down rapidly by visible light.

“But the IR spectrum involves much lower energy levels, at which organic solar panels cope admirably. For that reason they are ideally suited for this purpose.”

Several approaches

“Normally research progresses one step at a time, but thanks to the Foundation’s willingness to support more daring research, we can make substantial strides. It may transpire that some of our ideas are crazy, but we hope to find something really good,” says Mats.

Some of the ideas are about harnessing near IR-radiation, where most energy is found and it is easier to achieve good efficiency.

“There are two ways of getting into the IR spectrum. Either you change the molecule or, as my team is doing, you take existing materials and combine them in new ways to produce a material capable of absorbing IR radiation,” Mats explains.

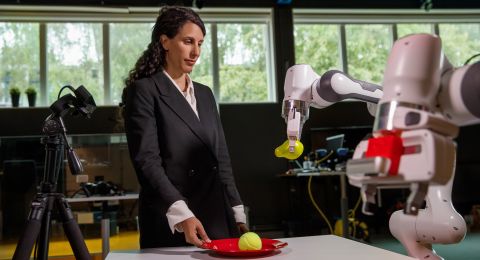

Another concept involves using nanotechnology to design a minute optical antenna.

“The idea is to use self-organizing structures found in biology, and decorate them with conductive molecules to create a ‘rectenna’ – a combination of a rectifier and an antenna, which converts electromagnetic radiation into direct current,” Xavier says during a guided tour of the dust-free clean lab where the tiny components will be made and tested.

His own research team will be studying thermoelectric phenomena, which is about ways of extracting electricity from heat.

Center of excellence

For many years, Norrköping in Sweden has been a center of excellence for research and development in the field of organic electronics. Two of the research leaders in the project, Magnus Berggren and Olle Inganäs, are Wallenberg Scholars. The Foundation has also awarded a grant for development of the advanced laboratory for printed electronics in Norrköping.

The research team collaborates closely with the Acreo research institute and Printed Electronics Arena (PEA), a commercialization center for printed and organic electronics. These actors help to guide promising research findings along the winding path to finished products or spin-off companies.

“They are not involved in this project, however, because this is a completely new technology. But hopefully we will be able to demonstrate a concept that works. If so, we will continue the journey with them,” Xavier adds.

Text Susanne Rosén

Translation Maxwell Arding

Photo Magnus Bergström

Read more about

Project Grant 2018

Replacing gasoline with paper fuel cells

Project Grant 2011

Recyclable paper electronics created in Norrköping

Wallenberg Scholas

Magnus Berggren

Wallenberg Scholars

Olle Inganäs