Project Grant 2018

Hydrogen Peroxide, Fuel and Energy Technology for the Future

Principal investigator:

Professor Magnus Berggren

Co-investigators:

Linköping University

Xavier Crispin

Thomas Ederth

Roger Gabrielsson

Eric Glowacki

Magnus Jonsson

Igor Zozoulenko

Institution:

Linköping University

Grant in SEK:

SEK 27,200,000 over five years

Magnus Berggren’s and his colleague’s vision is to power vehicles and the society of the future using oxygen and water. A project at Linköping University is combining the expertise of three research teams to turn hydrogen peroxide into the liquid fuel of the future.

“The best thing about our idea is that the end products are oxygen and water vapor, which creates a highly desirable energy cycle,” says Berggren, who is a professor of organic chemistry, and Director of the Laboratory of Organic Electronics (LOE).

In use last century

The idea of using hydrogen peroxide as a fuel dates back to the 1900s. But the advent of gasoline – an energy-dense fossil fuel – marked a rapid decline in the use of other energy carriers.

“Our goal is to contribute to a fossil fuel-free society. Simply replacing those fuels with electricity solves only part of the problem, since a large proportion of electricity is still produced using coal and oil. So we need to remove the fossil elements from the energy cycle,” Berggren says.

The project, entitled “Hydrogen Peroxide, Fuel and Energy Technology for the Future”, involves using electroactive materials combined with paper for twin purposes, as the electrode and electrocatalyst in fuel cells and in converters to produce hydrogen peroxide. Only oxygen, water and energy are added to the catalytic process, in which the energy input can come from solar cells, for example.

New uses for paper

Cutting-edge research in the field of organic electronics is taking place at LOE. The laboratory is home to a number of successful projects in which paper is one material finding new applications.

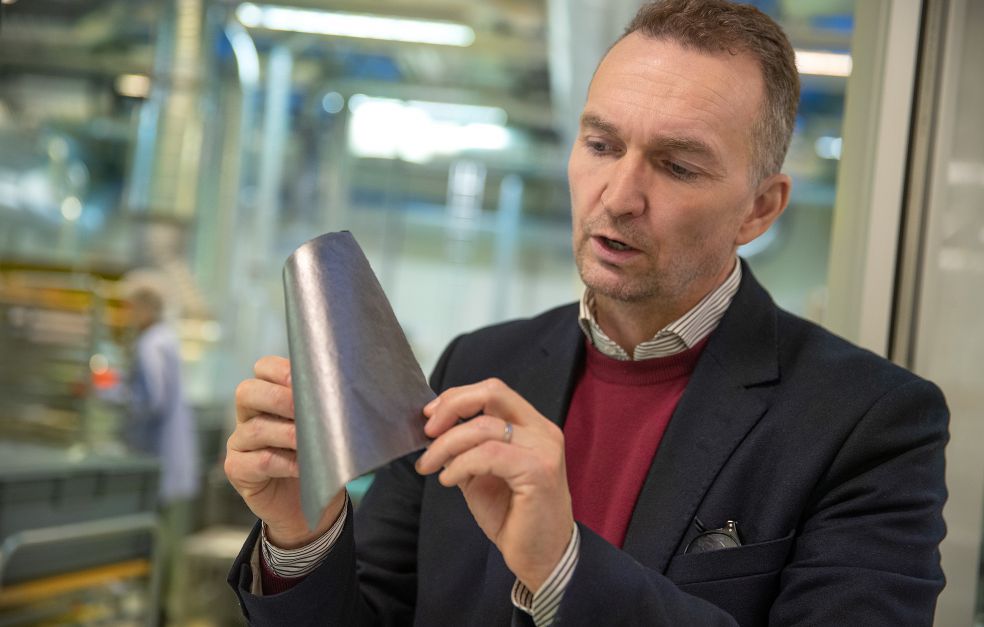

In Berggren’s project, cellulose fibers in the paper are coated with an electrical conductor. Oxygen and water are then added in the right proportions to interact with a catalyst driven either by electricity or by light.

The researchers have alternative catalysts at their disposal: either PEDOT, a plastic that conducts electricity, or organic crystals, which can use light to create photo/electro-catalytic reactions.

Hydrogen peroxide is produced in both cases. But there are several challenges. The cellulose fibers do indeed form a three-dimensional structure, but a large surface area is needed to create sufficiently rapid and extensive electrocatalysis.

“We need to create a paper about a gram of which represents an effective surface area of one hundred square meters. We aim to do this by varying the density of the paper, but it’s going to be a challenge.”

It is also necessary that the paper is sufficiently conductive, and that the flow of liquid and gas through it is high enough. The main limitation is how much oxygen can be dissolved in the water. Berggren elaborates:

“We can calculate what is possible in theory, but there are many parameters that can impose new limitations. We have the pieces of the puzzle – the question is whether they fit together.”

100 percent efficiency

One of the key pieces of the puzzle is the polymer PEDOT, whose electrocatalytic efficiency in producing H2O2 (hydrogen peroxide) is almost 100 percent.

“This gives us an excellent basis to work from, but we will see losses in the form of various side reactions. But throughout my entire research career I’ve never started development of a new technology with anything this efficient.”

The same process but in the opposite direction can then be used to drive cars of the future, which would run on hydrogen peroxide. The reverse process generates electricity, the residual products being oxygen and water.

“Our task is to develop this technique, and then let others decide whether it is realistic to scale it up for commercial use. But my gut feeling is that it will work.”

He thinks this fuel cell technology may soon offer an alternative or complement to battery technologies:

“We don’t consider current battery technology to be environmentally friendly on a large scale. And it’s easier to transport liquids than electricity stored in batteries or gases. Society already has the infrastructure in place to transport liquids.”

Long-term funding a springboard

The project would not have been possible without earlier research at LOE, also funded by Knut and Alice Wallenberg Foundation.

“The earlier funding gave us a springboard that has launched us in many directions – from battery technology and membranes to sensors and now to fuel cells. We can only feel an enormous sense of gratitude for the continued support we are receiving,” says Berggren.

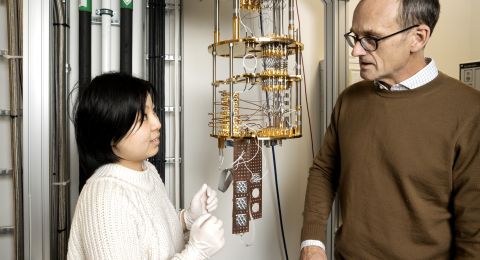

Also involved in the project is Eric Glowacki’s research team, contributing expertise on nanocrystals and electrocatalytic materials. The third team engaged in the project is headed by Xavier Crispin and specializes in energy materials.

One long-term goal is that the research will lead to a new spin-off. Berggren explains:

“We have some experience of the kind of research that should be spun off in corporate form. Our current project is a good example. This is a completely new product, which means it can be developed jointly by different industries such as the paper, oil and vehicle manufacturing sectors, for instance.”

Text Magnus Trogen Pahlén

Translation Maxwell Arding

Photo Magnus Bergström

More about

Wallenberg Scholar

Creating new research fields using organic electronics

Project Grant 2014

Making electricity from invisible sunbeams

Project Grant 2011

Recyclable paper electronics created in Norrköping