Smart textiles will soon be able to monitor your health or measure your movements. Thanks to electronic textiles, sensors can be woven into any fabric. But one problem remains: where will the power to run them come from?

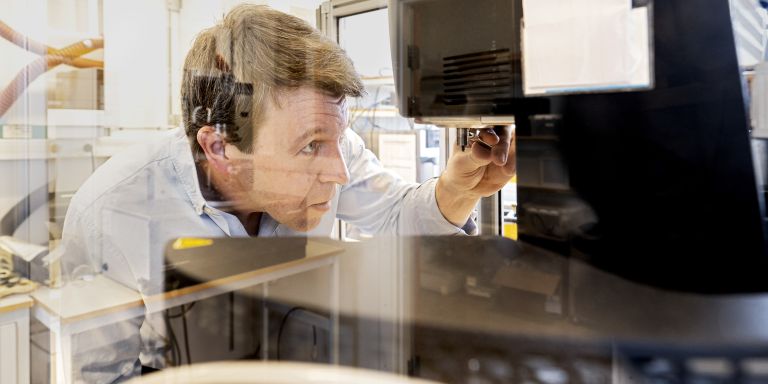

Christian Müller

Professor of Polymer Science

Wallenberg Academy Fellow/Wallenberg Scholar

Institution:

Chalmers University of Technology

Research field:

Polymer science and organic electronics

Christian Müller wants to use body heat to generate the electricity needed to drive our connected clothes.

“We can use the temperature difference between the inside and outside of a garment to generate electricity. I like the idea of sensors generating their own electricity by exploiting temperature differences in their surroundings,” says Müller.

Driving space probes

The ability to generate an electric potential from the difference between hot and cold was discovered during the early 19th century. The potential difference can be used to produce electric power, the amount of which depends on the electrical and thermal properties of the material. Inorganic thermoelectric materials are associated with a high manufacturing cost and tend to be harmful to the environment. That is why the technology is currently limited to high-end applications such as space exploration.

NASA’s space probe Perseverance was able to send back images from Mars in 2021 thanks to electricity produced by a radioisotope thermoelectric generator.

“New application areas may become feasible if carbon-based materials were used instead that are cheap to produce and can be incorporated in a circular and sustainable way.”

One appealing solution is to use conductive polymers. Polymers consist of long-chain molecules, which potentially impart unique mechanical properties such as stretchability and flexibility. This makes polymers an excellent choice for producing fibers and yarns that can be incorporated into fabrics.

“The grant from Knut and Alice Wallenberg Foundation gives me scientific freedom, which fosters the creativity needed to make progress in basic research.”

Machine-washable

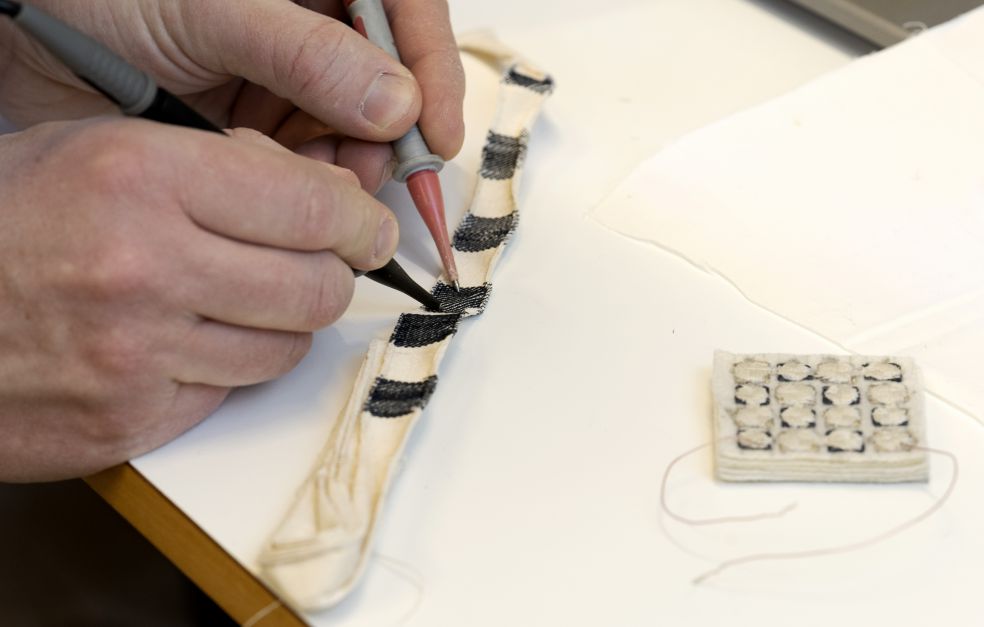

Müller demonstrates a foldable keyboard woven from conductive silk thread. The fabric itself was woven with help of the Gothenburg Handicraft Society.

“It was a fun project, in which the handicraft society played an important part. We took the fabric home to wash it in our washing machines so we could find out whether it retained its properties afterwards. It did,” he says.

Silk or cellulose threads are dyed using a conducting polymer based material, which can then be used to manufacture thermoelectric generators, for example with a standard sewing machine.

“It’s important that the materials we develop can be used in normal textile manufacturing equipment, so they can be used as widely as possible,” Müller says.

Not all polymers can conduct electricity, and hence can be used to manufacture thermoelectric generators. So called conjugated polymers are needed. These polymers can be made conducing through a process called doping, which involves the addition of a second molecule that removes an electron from the polymer or adds one to it. But much work remains to be done to understand how the process works, and how it can be optimized. In 2019 Müller’s research team published an article in Nature Materials jointly with other researchers from Sweden, Germany, the UK, the US and Saudi Arabia.

“The article describes how up to twice as many electrons could be transferred by choosing the right type of polymer and dopant molecule. The findings were a major advance for the field.”

Tailored properties

Doping also affects the mechanical properties of a polymer.

“Previously, many conducting polymers could not be used because they are too brittle instead of stretchable, but now we are starting to understand how we can use the doping process to control their mechanical properties. We want to develop methods of controlling both mechanical and electrical properties so we can tailor materials for different applications,” Müller explains.

The availability of materials with a wide portfolio of properties increases the scope for new applications.

“We want to extend our understanding of the interplay of electrical and mechanical properties to fields such as bioelectronics, organic solar cells and wearable electronics. The research field of organic electronics continues to expand. There is a growing understanding of the molecules we can use, and how we should process them to give them the right traits.”

He has likened his research to a fashion show. He and his colleagues devise imaginative examples of how the technology can be used. This then serves as an inspiration for the development of real-life applications.

“The academic environment provides a place where we can think freely. Funding from Knut and Alice Wallenberg Foundation has enabled me to establish an environment where my team has the time and opportunity to be creative.”

Through initiatives such as the Wallenberg Wood Science Center is his team able to interact with colleagues across Sweden.

“Together we develop the knowledge needed for the development of sustainable electronics. I very much enjoy basic research, since it enables me to do what my three-year-old daughter does every day: discover things for the first time. Research becomes a playful learning process, one that gives me great satisfaction.”

Müller is originally from Germany. His academic career has taken him to many corners of the world. One of the reasons he now works in Sweden is the strong support for academia and the excellent working environment. He also considers that the Swedish public places a high degree of trust in science, something that is absent in many other countries:

“Thanks to the Nobel Prize, every researcher in Sweden becomes a rock star once a year. When you receive that level of trust, you want to give something back to society.”

Text Magnus Trogen Pahlén

Translation Maxwell Arding

Photo Johan Wingborg